2022-02-13|admin

There are usually two ways to choose a coupling:

Select a suitable coupling according to the maximum torque, i.e. the peak torque required by the load should not exceed the rated torque of the coupling:

TKN ≧ 1.5 TAS Nm

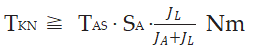

The coupling is selected according to the acceleration torque. At this time, the rotational inertia of the drive system needs to be considered. If the inertia ratio is large, the influence of the load factor in the calculation of the coupling specification will be reduced:

|

振动或负载系数 SA |

||

|

均匀载荷 |

非均匀载荷 |

高动态载荷 |

|

1 |

2 |

3-4 |

|

对伺服电机来说,负载系数通常为SA=2-3 |

||

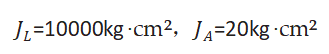

Calculation example:

Servo motor drive, maximum torque TAS=50Nm

Load factor SA=3

So ![]() ,It can be seen that when the load inertia is relatively large, the inertia of the coupling itself has little influence on the calculation results.

,It can be seen that when the load inertia is relatively large, the inertia of the coupling itself has little influence on the calculation results.

In addition to the torque, it is necessary to consider whether the speed meets the requirements. Most of the R+W couplings have been preliminarily balanced before leaving the factory. The default speed of some smaller models can reach 10000rpm. If the equipment needs The rotation speed is relatively high, and additional dynamic balancing treatment is required.