2022-06-02|admin

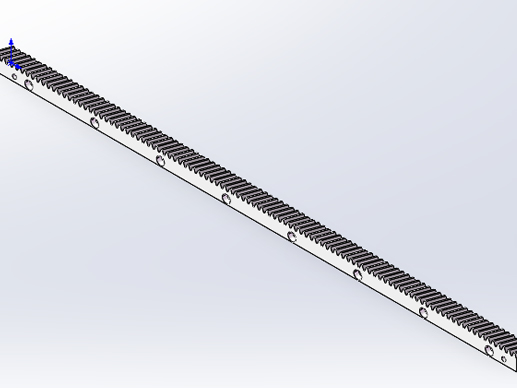

STRRONSE produces standard-sized precision racks, which are suitable for transmission industries such as truss, manipulators, machine tools, woodworking machinery, etc. Germany imports production equipment, supports customized services, rack selection and drawings need to be provided by contact technology.

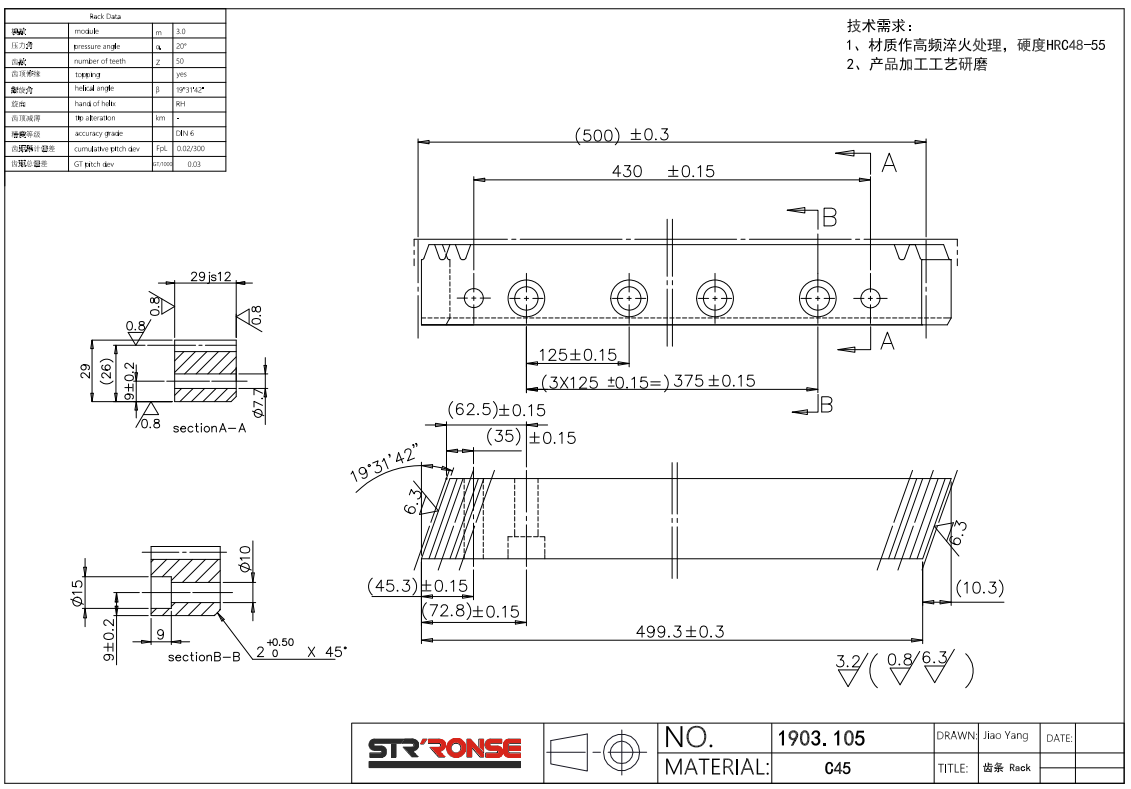

The key parameters in the rack drawing are module, rack size, pressure angle, helix angle, accuracy, mounting hole and pin hole position and other data. In the selection process, it is necessary to provide industry application and drive load data, dimensions and other values. The specific dimensions are provided as needed. The rack drawing needs to first calculate the load condition and then finally determine the rack module, accuracy and tooth shape.

The material of the rack is C45 carbon steel, and the process is grinding and fine milling. The grinding rack with 6S precision has high hardness, high load and high precision.

Hardness grade:

Grade 6 precision rack 50-55 HRC

Grade 8 precision rack 24-27 HRC

Grade 9 precision rack 50-55 HRC

The gear supports non-standard customization. When customizing the gear, you need to provide the gear drawing, the required module, precision, number of teeth, tooth shape and other parameters.

CAD drawings and rack models can be provided, or matched with the reducer model and load condition data information, and the complete system transmission scheme drawing selection.