Industry news|2022-02-10| admin

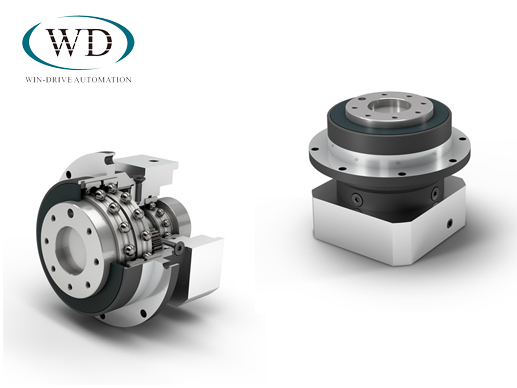

In modern industrial robots, servo motors driven by pulse signals and speed-regulated and decelerated have always been the main equipment power source. Then the servo motor itself can realize speed regulation. Why does the industry still use the servo planetary reducer as a transmission? Industrial robots generally perform repetitive actions according to the program set by the user to complete the same process. At this moment, in order to ensure that the industrial robot can reliably operate according to the set process in the production process, the positioning accuracy of the industrial robot is very high. And when the load is large, it is very uneconomical to blindly increase the power of the servo motor. Therefore, the servo planetary reducer as a "torsion increase and deceleration" comes in handy! The servo planetary reducer can make the servo motor work at a suitable speed, and accurately reduce the speed to the speed required by each part of the industrial robot, improve the rigidity of the mechanical body and output a larger torque. Compared with the general reducer, the robot joint gear motor is required to have the characteristics of short transmission chain, small size, high power, light weight and easy control. Therefore, many active machinery industries such as industrial robots currently use servo planetary reducers as the main precision transmission equipment.

How should the servo planetary reducer be selected? Next, Shenzhen Weidong will take you to understand

1. Calculate the output torque of the reducer, which is the required torque calculated by the transmission mechanism. The purpose of your choice of the reducer is to minimize the extra torque of the motor (that is, minimize the cost). + reducer (increased torque) = get a larger torque output. In fact, the use of reducer in the mechanical structure has many advantages, such as increasing torque, reducing inertia, reducing the impact of the transmission mechanism on the servo motor, self-locking transmission mechanism and so on. Of course, its central value is still to increase torque. So when you confirm the torque required by your transmission mechanism, then compare the torque of the servo motor you selected, and then the ratio of these two torques is the reduction ratio of the torque of the reducer you want to choose. Of course, we generally There will be some redundancy in the torque of the mechanism, so the transmission ratio should be selected slightly larger. Therefore, in this process, two parameters are very important, namely the final torque you need and the additional torque of the servo motor. As long as these two parameters are known, it is convenient to select the reduction ratio of the geared motor.

2. The calculation of the maximum speed of the transmission mechanism For the maximum speed of the transmission mechanism, the mechanical design engineer must confirm it by himself. Since this parameter involves the selection of the reduction ratio of the reducer, when we choose the reduction ratio, it is not to say It is possible to increase the reduction ratio infinitely. Since the larger the reduction ratio, although the torque will be larger, it also means that the output speed will be reduced, which also leads to a reduction in the operating speed of the entire transmission mechanism. Therefore, between torque and speed, we need to do a balance. On the premise of satisfying the transmission speed of the mechanical mechanism, try to increase the reduction ratio to increase the transmission torque. This is a reasonable choice. Of course, the transmission speed of a transmission mechanism is not completely determined by the reducer. The speed of the servo motor, the pitch of the transmission screw, the size of the gear, etc. are all decisive factors, so when we make structural planning, we need a comprehensive To consider, but the size of the reduction ratio is also a determining factor, we need to pay attention.

3. Selection of the installation method of the transmission mechanism For the selection of the reducer, in addition to the above parameter selection, the type and installation method of the reducer should also be selected. For example, the reducer you choose is a planetary reducer or a worm gear reducer. machine, it is a coaxial direct-connected type, or a 90-degree vertical device and so on. Especially for the selection of worm gear reducer, there are specific application scenarios, such as requiring the entire motion mechanism to have a self-locking function. We have such design requirements in many cases, such as when the transmission mechanism is a straight device, in order to prevent the mechanism After the motor is powered off, it falls, generally we choose a worm gear reducer. Of course, many people will raise the bar and say that they can choose a servo motor with a brake. In fact, it is possible in theory, and generally we will choose a brake motor for a servo motor in a straight direction, but we will find in actual use that the servo motor is energized. At the moment, many mechanisms will show a slight drop phenomenon. If you choose a worm gear reducer at this time, it can prevent such a phenomenon well, because the worm gear reducer has a self-locking function. Of course, this self-locking has a premise. The transmission ratio must be greater than a certain ratio, and the worm gear reducer can truly play the role of self-locking. If the reduction ratio is too small, it is still unreliable. I forgot the specific ratio (it seems to be If it is more than 30, not sure), you can have a good communication with the reducer manufacturer when you use it, they have relevant parameters. Therefore, it is also very important to choose what type of installation method is used, and it is not a choice to do whatever you want.

4. Selection of the transmission accuracy of the reducer The transmission accuracy of the reducer depends entirely on the accuracy requirements of the transmission mechanism you plan. You only need to match the corresponding parameters according to your function. Of course, this is a real cost, and the accuracy is higher. High, the higher the cost, and many times it is too high for you to accept, especially some good brands, you can't afford it. The transmission accuracy has a special mark, you only need to select the accuracy according to its explanation, if you are not satisfied, change the model, if you are not satisfied, then change the brand.

5. The equipment of the reducer interface In the process of selecting the reducer, there are two interfaces of the reducer that we need to clarify through the drawings. The first interface is the interface between the reducer and the servo motor. This is generally customized. The reducer manufacturer will customize the interface of the reducer according to the interface of the servo motor selected by the customer. Therefore, when communicating with the reducer supplier , you need to provide the interface of the servo motor to them.

The second is the output interface of the reducer. Generally speaking, we choose this interface according to the standard of the reducer supplier, unless you have special requirements. For example, the output shaft you require is a smooth shaft (without a keyway), or a shaft with a keyway is required, or there are special requirements for the stop and fastening screws of the device, etc., which can be customized according to the wishes and needs of the planning engineer. .

Why industrial robots use the servo planetary reducer and how to select the servo planetary reducer? The answer is given above. There are also some points to pay attention to in the selection process, the purpose is to make the mechanism work better. I hope it can help you. For more planetary reducer knowledge, you can pay attention to Shenzhen Weidong Automation!