Industry news|2022-04-13| admin

Industrial robots In recent years, with the rapid development of the economy, the level of science and technology has been increasing. Automation and AI have become synonymous with the new century, and will also become a major global trend in the future. The most important basic component of the industry is also the core component of the movement: the precision reducer. The reducer is an independent component composed of a gear drive, a worm drive and a gear worm drive enclosed in a rigid housing, and is often used as a reduction drive between the prime mover and the working equipment. It plays the role of matching the rotational speed and transmitting torque between the prime mover and the working or actuator mechanism, and is widely used in modern equipment.

Reducers are generally used for low-speed, high-torque transmission equipment. The electrical appliance, internal combustion engine or other high-speed power is meshed with the large gear on the output shaft through the small-toothed gear on the input shaft of the reducer to achieve the purpose of deceleration. Ordinary reducers also have several pairs of gears with the same principle to achieve the ideal reduction effect. The gear ratio of the large and small gears is the transmission ratio.

In industrial robots, the reducer is one of the three important components, and its cost can account for one-third of the total cost of the robot. Because industrial robots have high requirements for reducers, the selection of precision reducers should be based on torsional stiffness, starting torque, transmission accuracy, transmission error, and transmission efficiency. At present, there are only three types of reducers commonly used in industrial robots: precision harmonic reducer, precision planetary reducer and precision RV reducer, which can meet the requirements of industrial robots.

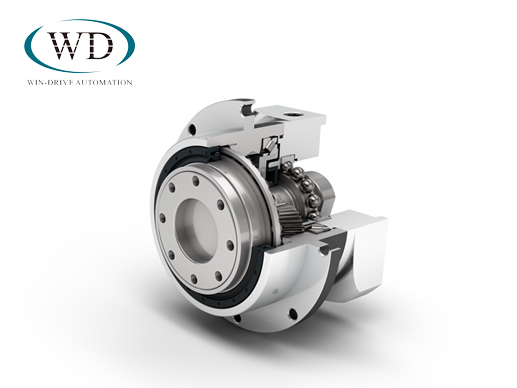

RV reducer

The RV reducer is developed on the basis of the cycloidal pinwheel drive, with two-stage deceleration and a central disc support structure. Since it was put into the market in 1986, it has become the "royal" reducer for robots with its advantages of large transmission ratio, high transmission efficiency, high motion accuracy, small backlash, low vibration, high rigidity and high reliability.

Harmonic reducer

The harmonic reducer consists of three parts: harmonic generator, compliance theory and rigid wheel. Its working principle is that the harmonic generator makes the flexible wheel produce controllable elastic deformation, and the flexible wheel meshes with the rigid wheel to transmit power to achieve the purpose of deceleration. Depending on the wave generator, there are cam type, roller type and eccentric disc type.

Planetary reducer

A planetary reducer, as the name suggests, is a reducer in which three planetary gears rotate around a sun gear. The working principle of the planetary reducer is that when the sun gear rotates under the drive of the electric appliance, the meshing action with the planetary gear will make the planetary gear rotate. At the same time, since the other side of the planetary gear meshes with the ring gear on the inner wall of the housing, under the action of the rotational driving force, the planetary gear will roll on the ring gear in the direction of the sun gear's rotation, forming around the sun gear. The "revolution" movement. Planetary reducer has the advantages of small size, light weight, high bearing capacity, long service life, stable operation and low noise. It features power splitting and multi-tooth meshing. It is a versatile industrial product. Its performance is comparable to other military-grade planetary reducer products, but with the price of industrial-grade products, it is used in a wide range of industrial occasions.

The difference between RV reducer and harmonic reducer

RV reducers are generally used in industrial robots with large loads, and harmonic reducers are mainly used in industrial robots with small loads. Nabotsk and Murata are the representatives of the RV reducer, and the harmonic reducer is basically monopolized by the Japanese Hamernaco harmonic reducer

Harmonic reducer is a kind of harmonic drive, including harmonic accelerator and harmonic reducer. Harmonic reducers mainly include rigid wheels, flexible wheels and wave generators, all of which are indispensable.

Among them, the number of teeth of the rigid wheel is slightly larger than that of the flexible wheel. The length of the wave generator is greater than the diameter of the inner circle of the undeformed flex wheel: when the wave generator is installed on the inner circle of the flex wheel, the flex wheel is elastically deformed into an ellipse, so that the teeth of the flex wheel on its long axis are inserted into the rigid wheel In the tooth slot of , the flex wheel is fully meshed; while the teeth of the two wheels at the short axis are not in contact at all, so they are in a disengaged state.

The process from engagement to disengagement is in a state of engagement or engagement. When the wave maker rotates continuously, the flexible wheel is forced to deform continuously, so that the teeth of the two wheels change their respective working states in the process of meshing, occlusal, occlusal, and disengagement, resulting in the so-called staggered tooth movement, thereby realizing active generation. Motion transfer between wave generator and flexible wheel.

RV transmission is a new type of transmission developed on the basis of traditional needle pendulum planetary transmission. It not only overcomes the shortcomings of general needle pendulum transmission, but also has a series of advantages such as small size, light weight, wide transmission ratio range, long service life, stable precision, high efficiency and smooth transmission.

The RV reducer consists of a cycloidal pinwheel and a planetary carrier. Due to its small size, strong impact resistance, large torque, high positioning accuracy, low vibration, and large reduction ratio, it is widely used in industrial robots, machine beds, medical testing equipment, satellite receiving systems and other fields. Compared with the harmonic drive commonly used in robots, it has much higher fatigue strength, stiffness and service life, and the backlash accuracy is stable. Unlike harmonic drives, its motion accuracy decreases significantly with age. Therefore, RV reducers are widely used in high-precision robot drives in many countries in the world. Therefore, this RV reducer has the development trend of gradually replacing the harmonic reducer in the advanced robot drive.

In recent years, as the market for industrial and life-assistance robots continues to expand, the demand for high-precision small-modulus gears inside precision reducers for robot joints has also surged. What are the types of reducers commonly used in industrial robots? The above is the relevant knowledge, I hope it can help you.