Industry news|2022-04-18| admin

The backlash of the planetary gear gearbox, also known as the backlash, is generally defined as: when the output end is fixed, the input end rotates clockwise and counterclockwise, so that the input end generates a torque of ±2% of the rated torque, the input end of the gearbox There is a slight angular displacement, which is the backlash. The unit is "cents", which is also one sixtieth of a degree.

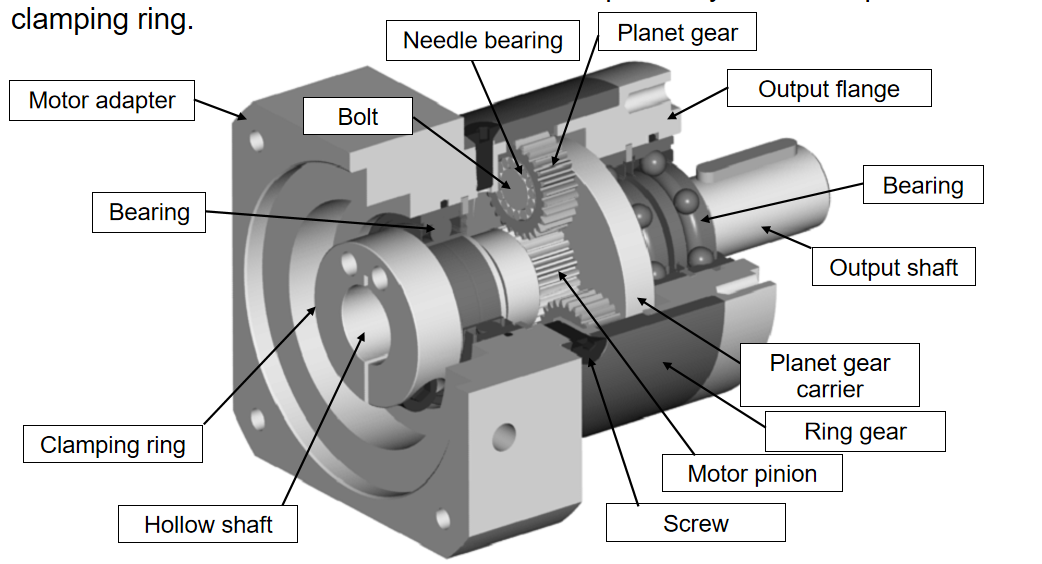

With the precision of the machinery industry, the requirements for the volume, efficiency and reliability of the gearbox are getting higher and higher, and the internal structure of the precision gearbox is very important. The internal structure of the planetary gearbox is shown in the figure. The middle sun gear and the output end of the gearbox are integrated, and form the inner planetary carrier of the gearbox with the surrounding planetary gears. The outer ring gear is connected to the gearbox housing and meshes with the planetary gears. , which constitutes the entire transmission system.

When the gearbox is working, the power is input from the input end of the gearbox, which drives the sun gear to run, and the planetary gear meshes with the inner gear of the housing, and the whole not only rotates, but also revolves around the sun gear. The planetary gear is proportional to the radius gear of the sun gear, and the speed ratio of the gearbox is also directly related.

The backlash accuracy grade of the planetary gearbox refers to the gear accuracy grade. The national standard specifies 12 precision grades for gears. In the order of accuracy, they are called Level 1, Level 2... Level 7, Level 8, Level 9, Level 10, Level 11, Level 12

Each grade of gear accuracy includes three specifications: gear motion accuracy; gear working stability accuracy and tooth surface contact accuracy. The motion accuracy specification determines all the error values for the rotational angle of the gears in one revolution, thus ensuring a constant transmission ratio. The working stability specification of the gear determines the repetition value of all errors in one revolution of the inner angle of the gear to ensure smooth transmission and reduce vibration and noise. The contact accuracy specification of the teeth determines the proportion of the contact spot of the meshing teeth in the gear transmission, thereby ensuring uniform load distribution on the tooth surface.

When detecting the backlash of the planetary gearbox, it is necessary to measure in the reverse direction according to the definition of backlash:

Fix the input end, load ±2% rated torque on the output end, and rotate the output end of the gearbox in the forward and counterclockwise directions. At this time, a small angle deviation will be generated at the output end of the gearbox. This angle deviation value is our the desired backlash.

The bearing size of the output shaft of the planetary gearbox is limited, and there is no obvious change in the measured structure. Usually, the method of magnification measurement is adopted. A pendulum rod with a radius r is added to the output shaft of the gearbox, and a force of size F is applied at the radius r. , then at the same point on the pendulum rod, the front and rear deflection amount x will be generated, and the change α of the deflection amount x reverse thrust angle can be measured.

Because a certain amount of torque is required to overcome all the backlash in the system, the most accurate method is to measure the gearbox for a complete reciprocating cycle of the load (clockwise from zero to the rated load torque value, then unload, counterclockwise torque reverse to rated torque value).

The above is the relevant knowledge about the backlash level and measurement method of the servo planetary gearbox. Through the swing distance of the output end of the gearbox, we can directly and objectively judge whether there is a problem with the accuracy of the gearbox, thereby improving professionalism and work efficiency.