Industry news|2022-05-23| admin

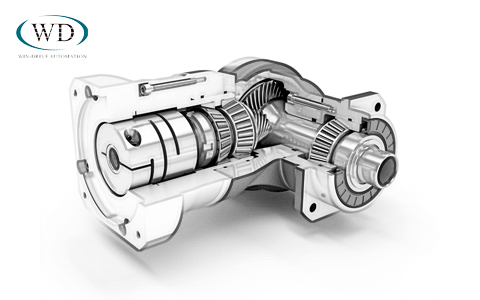

In the mechanical transmission industry, the planetary reducer in the reducer series is widely used due to its advantages of small size, high efficiency, high precision and low noise, mainly in high-precision industries such as machine tools, printing, robot automation, and lithium batteries. During the installation process of the right angle planetary reducer, because the installation process is not standardized, the shaft of the reducer is broken or the internal gear is seriously worn and other unnecessary losses. The reducer should be installed reasonably to avoid a series of unnecessary losses. Next, the installation process and precautions of the right-angle planetary reducer will be introduced.

Right angle planetary reducer installation process

1. Before installation, it is necessary to confirm the integrity of the motor and the right-angle planetary reducer, and check whether the dimensions of the parts connected to the motor and the reducer match, mainly the positioning boss of the motor, the input end aperture of the reducer and other matching dimensions .

2. Unscrew the mounting screws on the outside of the mounting flange of the reducer, adjust the locking ring of the reducer to align the mounting holes between the reducer and the motor, and connect the motor and the reducer together. During the installation process, it is necessary to Make sure that the output shaft of the reducer is concentric with the input end of the motor, and the outer flange is parallel.

Precautions for installation of right angle planetary reducer

Before installation, the input end and output shaft of the reducer and motor need to be rust-proofed to ensure the tightness of the connection and the flexibility of the operation, and to prevent unnecessary wear.

During the installation process, the concentricity is inconsistent due to misalignment, which will cause the shaft of the motor to break or the internal gear of the reducer to wear. When installing, do not hit the installation with heavy objects to prevent excessive axial force or radial force from damaging the bearings or gears of the reducer

When installing the motor and reducer, the keyway of the motor shaft can be perpendicular to the locking bolt. In order to ensure that the force is even after installation, the diagonal bolts are screwed up and positioned, and the bolts are installed one by one. The bolts need to be tightened and checked with a torque wrench during this process.

The installation between the reducer and the motor or other mechanical equipment is mainly to ensure whether the concentricity between the reducer and the driving part is consistent.

The above is the relevant knowledge and precautions about the installation of the right angle planetary reducer. The direct planetary reducer has a compact structure and can be installed well in some structures with limited space. The types of bearings are diversified, and the output shaft has flanged, hollow , shaft output, can be adapted to different scenarios.