Industry news|2022-05-26| admin

There are many types of reducers, which can be divided into worm gear reducers, cycloid reducers and planetary reducers according to the type. Among them, the planetary reducer is also called a planetary gear reducer. In detail, there is a certain difference between a planetary reducer and a gear reducer. What is the difference between a planetary reducer and a gear reducer? Next, analyze the difference between planetary reducer and gear reducer according to different angles.

First, the working principle is different

Planetary reducer: The motor is directly connected, and the sun gear drives the planetary gears on the planetary gear carrier. The entire planetary gear system rotates along the inner gear ring while revolving, and the planetary gear carrier is connected to the output shaft to achieve the purpose of deceleration. The working principle is similar to the gear reducer, but it has two characteristics of "power splitting" and "multi-tooth meshing" that the gear reducer cannot achieve. These two features are often used in transmissions and clutches. In addition, the planetary reducer is a military product in the field of reducers, but the price is industrial, and it is widely used in industrial equipment manufacturing.

Gear reducer: The use of gear transmission at all levels is used to reduce the speed. For example, the small gear can drive the large gear to achieve a certain reduction ratio. The motor provides the rotational speed, and the drive shaft connects the motor and the gear reducer. The more gear stages of the reducer, the slower the speed, the greater the torque, and the stronger the bearing capacity. The disadvantage is that the noise will be relatively large. When designing the gear reducer, the power demand mode is basically customized, that is, the parameters such as the speed and torque of the gear reducer are customized according to the needs.

Second, the structure is different

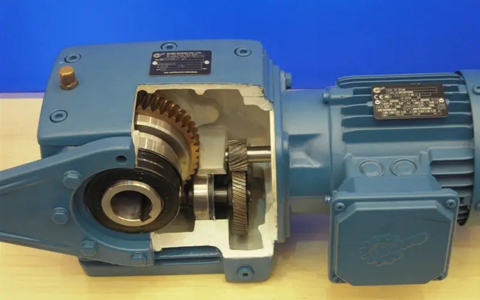

Planetary reducer: Planetary reducer is an extension and optimization of gear reducer. The main transmission structure of the planetary reducer consists of a sun gear, a planetary gear, an inner gear ring, a planet carrier, a sealing ring and a transmission bearing. Compared with the gear reducer, its manufacturing process is more complicated, the performance is better, and the transmission is more reliable.

Gear reducer: A combination of a geared motor and a large reducer, including the prime mover and working device gears. The external main structure of the gear reducer is composed of a drive shaft, a spur gear and a motor; the internal structure is mainly composed of multi-stage gears, which is simpler in structure than the planetary reducer. Each gear is driven by multiple gears of different sizes, thereby forming a reduction ratio and At the same time, the output speed is also reduced, and the torque is increased to achieve the ideal driving effect.

Third, different uses

Planetary reducer: It can be used as a supporting component in industries such as robot, laser cutting, printing, lithium battery, coating machine, packaging, manipulator, etc. It is also widely used in automobile, communication, mechanical equipment, electronic products, medical machinery and other fields.

Gear reducer: widely used in large-scale mining, steel, chemical, port, environmental protection and other fields.

Fourth, the characteristics are different

Planetary reducer: with high rigidity, high precision, high transmission efficiency and a wide range of optional transmission ratios. Small size, light weight, high bearing capacity, long service life, stable operation, low noise and large output torque. It can realize power split and multi-tooth meshing. 4. Material and machining accuracy, high production cost.

Gear reducer: no cooling, maintenance-free grease, long service life and high output efficiency; the shell is made of alloy steel, with high coaxiality and good dynamic balance, and can be installed on various machining center machine tools. Accuracy and torque are lower than planetary reducers.

Fifth, the deceleration range is inconsistent.

Planetary reducer: the minimum single-stage reduction ratio is 3, the maximum generally does not exceed 10, and the common reduction ratio is 3/4/5/7/8/10.

Gear reducer: generally no more than 3.

The above is the relevant knowledge of the difference between planetary reducer and gear reducer. Planetary reducer belongs to the category of gear reducer, but it is different from gear reducer, mainly its internal structure is different, and the application industry is also very different, and planetary reducer is more of a precision industry application, and the characteristics of the reducer are also different. identical.