Industry news|2022-05-27| admin

In the past in the traditional machinery industry, the most commonly used transmission equipment is the lead screw. The lead screw has the advantages of high transmission efficiency and accurate positioning. The disadvantage is that it is expensive and has a short stroke. However, with the development of the machinery industry, the stroke of the parts we need to process continues to increase, and the shortcomings of the screw become more and more obvious. In order to better adapt to the development of the industry, the rack and pinion came into being. The transmission not only has high transmission accuracy and low cost, but also can be infinitely spliced to increase the stroke. It is more and more common in the machining industry today. Representative industries such as: laser cutting machine, the seventh axis of the ground rail, gantry machine tool processing, gantry Truss and other industries.

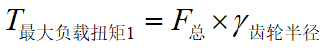

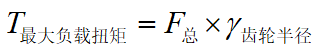

With the increasing use of rack and pinion, the selection of rack and pinion is particularly important, so the selection of rack and pinion needs to calculate the maximum load torque. We all know that rack and pinion transmission converts rotary motion into linear motion. Before calculating the maximum torque of the load, the thrust needs to be calculated, and then the torque can be obtained by multiplying it by the gear radius. The detailed calculation is as follows:

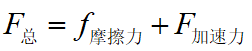

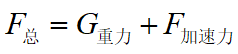

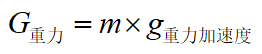

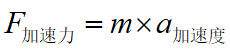

If it is moving horizontally, the force that needs to be calculated is

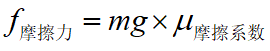

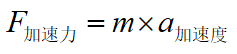

So

If it is moving in the vertical direction, the force that needs to be calculated is

So

If it is moving in the vertical direction, the force that needs to be calculated is