Industry news|2022-02-21| admin

1. When the reducer is under load, the motor does not rotate;

Possible reasons: the voltage level is too low, the gear system is damaged, and the overload is running; Troubleshooting: Check whether the power cord is too long or too thin, and send professionals to the factory to repair and reduce the load

2. The reducer is abnormally hot

Possible reasons: overload operation, high starting and stopping frequency, bearing wear, high or low voltage; troubleshooting: reduce the load, reduce the load, reduce the frequency of use, repair or replace, and confirm whether the voltage is normal.

3. The noise of the reducer is too large

Possible reasons: noisy and continuous: bearing damage, gear wear, occasional noise: gear damage, foreign matter stuck; solution: send it to a professional manufacturer for repair, contact customer service.

4. The vibration of the reducer is too large

Possible reasons: gears, bearings are worn, fixed assets are bad, screws are loose; cleaning method: send to professional development factory for repair and re-lock

5. The operating noise of the reducer is abnormal and unstable

Possible reasons: oil pollution or lack of oil; cleaning methods: check the color, concentration, oil level of the oil

6, reducer oil leakage

Oil leakage problem parts: at the motor passing flange, at the motor and oil seal, at the reducer flange, at the oil seal of a part of the output; possible reasons: the screw is loose, the sealing ring is damaged; cleaning method: re-lock Tighten and replace it, and contact the planetary reducer manufacturer

7. The output shaft does not rotate when the motor of the reducer rotates

Possible reason: the shaft key connection of the planetary reducer is damaged; cleaning method: send it to the planetary reducer manufacturer for repair

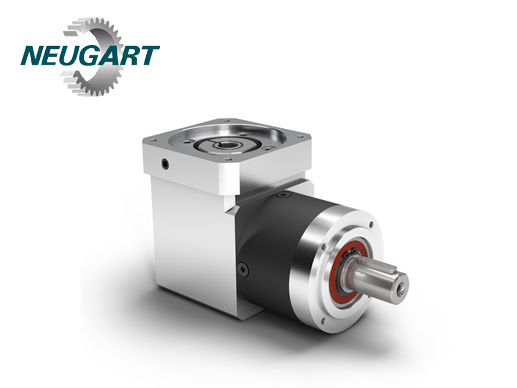

In the process of using the right angle reducer, if there is a fault, the equipment must be fully inspected first, because it only passes a very comprehensive equipment test. Can have a more comprehensive grasp of the use of equipment, as long as these things can be properly handled when using the equipment, it will definitely bring better help to the operation. When there is a problem with the right-angle servo reducer, a professional technician is required to analyze and test. When testing the equipment, the technician can understand the details of the equipment more clearly. As long as the equipment can summarize the data and deal with these problems when the equipment fails, the equipment can persist. Excellent use status can also improve the overall work efficiency.