Industry news|2022-03-07| admin

1. Input terminal

When the Neugart planetary gearbox is connected to the servo motor, there are threaded holes on the adapter plate of the planetary gearbox, and through holes on the servo motor. Specifications: For example, the M8 threaded hole on the adapter plate of the gearbox, the diameter of the through hole of the servo motor should be larger than φ8mm , less than φ9mm. The reason why it cannot be larger than 9mm is that there should be no excessive clearance after the screw is tightened. The distributed threaded hole screws should be loaded with the same torque to ensure the balance of the force system, so that the servo motor can output torque smoothly without jumping too much. When the output is at high speed, the motor shaft will not be subjected to radial force, resulting in broken shaft or radial bending of the shaft.

The diameter of the clamping hub of the planetary gearbox should be larger than the diameter of the motor shaft, and the length of the adapter plate should also be larger than the length of the motor shaft before the motor can be connected to the gearbox.

The tightening screw should choose the thread strength of 12.9. We must have encountered the situation that the diameter of the motor shaft is smaller than the diameter of the tightening hub. Our tightening hub will increase the clamping sleeve to reduce the diameter of the tightening hub when dealing with this situation, so we The planetary gearbox can be matched with servo motors and stepper motors in automation equipment.

The adapter plate of the planetary gearbox will also be customized according to the size of the motor, which is a non-standard customization. Our standard ones are:

1, 2 Piece - Round Universal Flange.

2. 2 Piece - Square Universal Flange.

3. One-piece single flange.

4. There is no suitable motor flange - circular universal flange.

5. No motor adapter flange-input shaft. The threaded holes distributed on the adapter plate can also be adapted according to the through holes distributed on the motor flange.

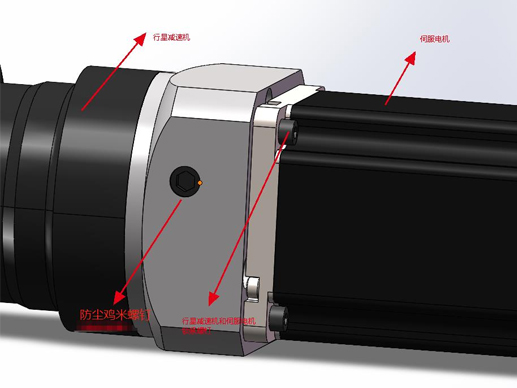

When tightening or loosening the motor shaft, be careful not to screw the clamping hub locking screw with the sliding wire. The best installation method is to keep the clamping hub screw and the dustproof chicken screw in a horizontal position (the clamping hub screw is in the matching position) Inside the adapter plate) the light will be very weak inside the adapter plate, and a light source is needed to find the clamping hub screws. The specific steps are: under a certain light source, rotate the output shaft, the clamping hub will rotate along with it, and the motor shaft can be disassembled or tightened when it is on the same level as the dustproof screw of the machine. This installation method has its shortcomings. , it is easy to slip the clamping hub screws. The structure needs to be further optimized and improved.