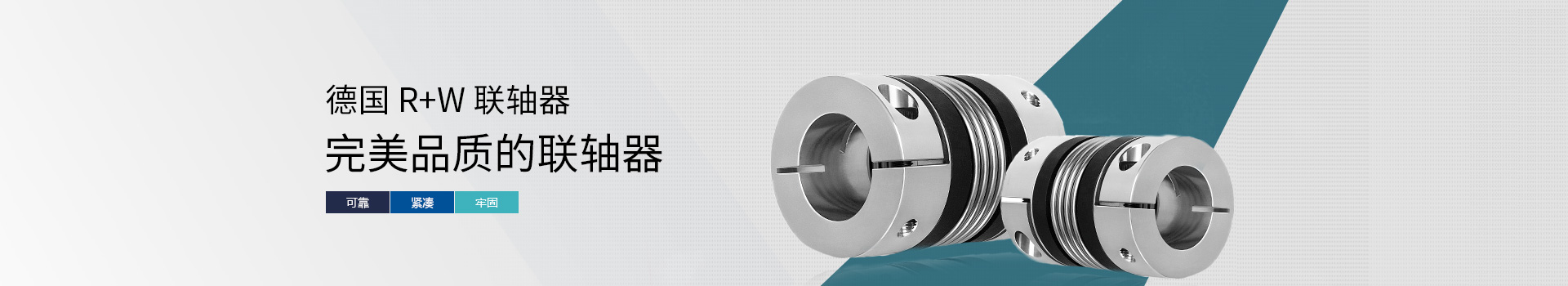

Structure:

Two coupling sleeves with concave claws and high concentricity.

One side of the safety coupling is integrated.

The elastic ring can choose the specification pattern A or B.

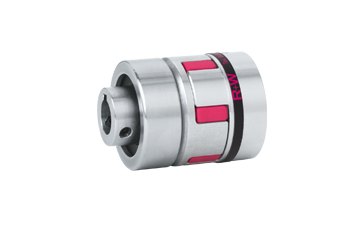

Temperature range: depends on the quincunx elastic ring selected.

Torsional rigidity: quincunx elastic rings with different shore hardness are provided for the optimization of transmission system.

Fit clearance: shaft sleeve connection 0.01 - 0.05 mm.

Material Science:

Safety components: made of high elastic steel, the clamping groove ball is made of hardened steel

Coupling sleeve: high strength aluminum

Elastic ring: precision molded, extremely wear-resistant plastic.

Speed: the wear is negligible when the disengagement reaches 200 rpm, and higher speed: ask the manufacturer through terminal consultation if necessary.

Technical parameters:

Rated torque: 9-200 Nm

Shaft diameter 6 - 45 mm

ESL safety coupling product features:

The zero back gap structure is confirmed by the R + W principle

Fast stop in milliseconds

The torque of safety coupling is stepless and adjustable

Precise torque limit

Compact and safe coupling

Electrical insulation

Plug in coupling

| SIZE | 5 | 10 | 20 | 60 | 150 |

| Torque setting possible | 1-6 | 1-12 | 3-19 | 5-60 | 20-150 |

| Overall length | 34 | 45 | 64 | 80 | 90 |

| Inside diameter | 6-15 | 6-18 | 8-25 | 12-32 | 19-38 |

| Moment of inertia | 0.01 | 0.02 | 0.08 | 0.15 | 0.5 |