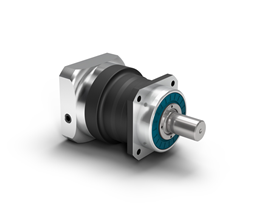

The precision planetary gearbox for maximum loads with particularly quiet drive and flange output shaft.

Thanks to its standardized flange interface, our PSFN can be installed easily and reliably. Our Neugart-designed helical teeth makes additional noise absorption measures absolute. Thanks to its high tilting moment, you may demand the utmost from this precision planetary gearbox.

PSBN planetary gearbox is a high-load, quiet operation, using a flanged output shaft. Since this gearbox adopts a standardized flange interface, the installation of PSFN is very convenient and safe. Our high-precision helical gears make other noise reduction measures useless. And because of the high anti-tilting moment of the gearbox, this high-precision planetary gearbox can complete many difficult tasks.

product description

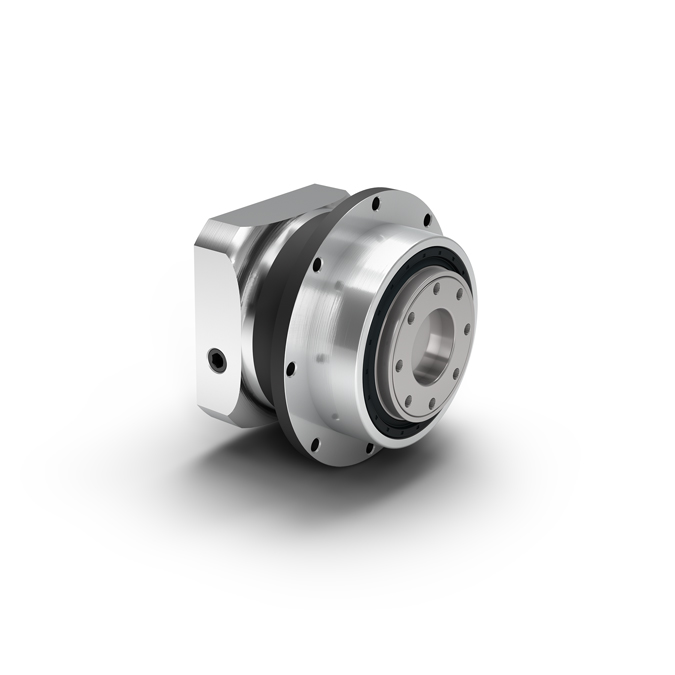

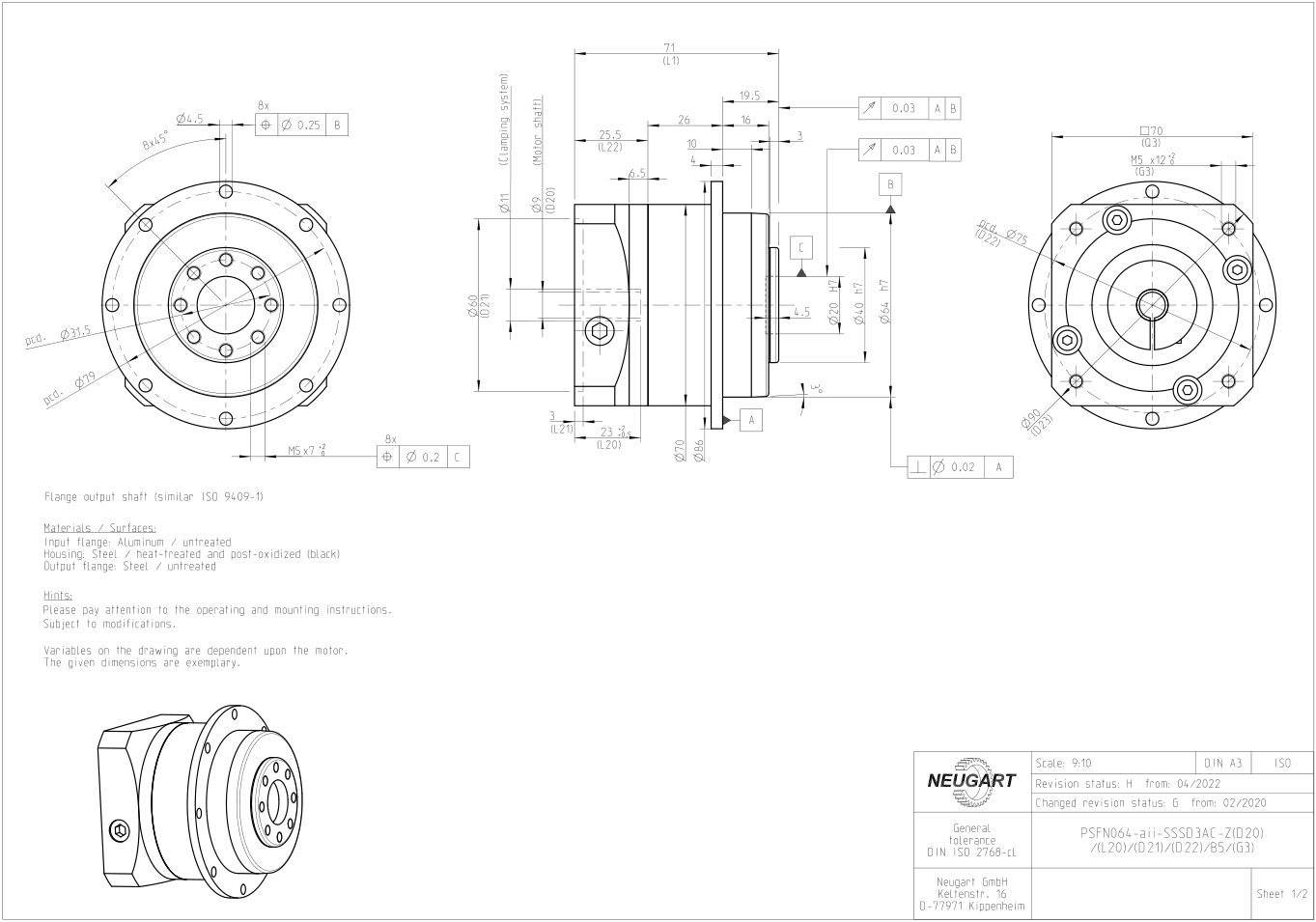

The PSFN planetary gearbox adopts a standardized flange interface that meets the requirements of EN ISO 9409-1, and the installation of the drive components will be very fast and convenient. And the optional positioning pin hole also provides additional guarantee for the safety of the gearbox. PSFN is very quiet during operation, because we have adopted the self-developed high-precision helical gear design, which does not require additional noise reduction and sound insulation measures on the machine, which saves a certain amount of cost while reducing noise. The load capacity of PSFN is very good, so it can withstand high radial and axial forces, which can play a great role in the structural design for rotary table or rack and pinion applications. Of course, the performance of the gearbox will not be affected in any way.

This gearbox has a small return clearance and can be installed in any position, the input flange can be adapted to special motors, and it has an optimized moment of inertia system. Equipped with preloaded angular contact roller bearings, this gearbox features a flanged output shaft with a round oversized output flange and radial shaft seal. The service life of this gearbox is as long as 20000h, the working temperature range is -25-90℃, there are three kinds of lubrication methods: low temperature, food grade and standard, the rated torque is 28-950Nm, the radial force is 2150-23000N, and the axial force is 4300 -16000N, the return clearance is 1-5 arc minutes, and can be customized to be less than 1 arc minute. The specific product model parameters are determined according to the model selection, and three-dimensional technical drawings and system selection plans are provided.

NEUGART planetary gearbox PSFN series adopts a standardized output flange, so it can directly install gears, couplings, synchronous pulleys, etc. connected with standard flanges, and can be equipped with positioning pin holes to make the fit more firm.

PSFN is a high-precision series gearbox. The backlash of the primary reduction ratio is less than 3 arc minutes, and the backlash of the secondary reduction ratio is less than 5 arc minutes. Except the minimum specification, the other specifications can be customized to be less than 1 arc point.

The gearbox adopts high-precision helical gears, which runs smoothly and has excellent noise control. And the internal gears are all carbonitrided. Compared with other brands of gearboxs, under the same working conditions, our gearboxs can have a longer service life and the accuracy will decrease more slowly.

Different from domestic or Japanese flange output gearboxs, all specifications of Newcastle PSFN use single row tapered roller bearings as the output bearings of the gearbox, so this gearbox can not only withstand extremely high axial force and Radial force, and the structure is very compact, the overall rigidity is extremely high, it is very suitable for high-speed and high-dynamic rack and pinion transmission, so this model is widely used in laser cutting machines.

When PSFN is used in conjunction with gears, we need to select the appropriate gears according to the flange size of the gearbox of different specifications. When the flange is large and the gear is small and cannot be installed directly, an adapter plate can be used for installation. In addition, we also need to pay attention to the influence of connecting bolts on the maximum transmitted torque, and the maximum torque that can be transmitted by different bolts is different. Therefore, in the design and selection, in addition to the strength of the gear and the gearbox itself, it is also necessary to consider the maximum torque that the bolts at the connection can transmit.

Product advantages

Standardized flange interface

runs very quietly

high load capacity

high sealing

Small and exquisite

Inclined gears bring quality improvement

Optional

return clearance

Various types of output shafts

Lubricate

Optimized tensioning system

installed pinion

Use

Lithium battery industry, coating machine, printing, laser cutting, manipulator

Features

Easy installation, quiet operation, high load capacity

PSFN flange gearbox size drawing download:

PSFN gearbox drawing download

| Gearbox characteristics | PSFN064 | PSFN090 | PSFN110 | PSFN140 | PSFN200 | P | |

| I | 4,5,7,8,10 | 1 | |||||

| I | 16,20,25,35,40,50,70,100 | 2 | |||||

| Service life |

h |

20.000 | |||||

| Service life at T2N×0.88 | h | 30.000 | |||||

| Efficiency at full load | % | 96-97 | |||||

| Min operating temperature/max operating temperature | ℃ | -25/90 | |||||

| Protection class |

IP65 |

||||||

| Standard lubrication | Grease (lifetime lubrication) | ||||||

| Food grade lubrication | Grease (lifetime lubrication) | ||||||

| Low temperature lubrication | Grease (lifetime lubrication) | ||||||

| Installation position | Any | ||||||

| Standard backlash | arcmin | <3-<5 | |||||

| Reduced backlash | arcmin | <2 | <1 | <1 | <1 | <1 | |

| Torsional stiffness | Nm/arcmin | 8.2-13.3 | 21.0-31.0 | 55.0-81.0 | 127.0-218.0 |

365.0-668.0 |

|

| Gearbox weight | kg | 1.4-2.1 | 3.0-3.7 | 5.0-6.5 | 11.7-13.8 | 28.5-34.8 | |

| Standard surface | Housing: Steel - heat-treated and post-oxidized(black) | ||||||

| Running noise | dB/(A) | 57 | 58 | 63 | 66 | 68 | |

| Max bending moment based on the gearbox input flange | Nm | 18 | 18/38 | 38/80 | 80/180 | 180/300 | |

Nominal Output torque

| PSFN064 | PSFN090 | PSFN110 | PSFN140 | PSFN200 | I | P |

|

39 |

80 | 180 | 470 | 950 | 4 | 1 |

| 40 | 80 | 175 | 405 | 950 | 5 | |

|

37 |

78 | 175 | 355 | 900 | 7 | |

|

39 |

75 | 155 | 350 | - | 8 | |

| 28 |

59 |

140 | 305 | 750 |

10 |

|

| 39 | 80 | 180 | 450 | 950 | 16 |

2 |

| 39 | 80 | 180 | 450 | 950 | 20 | |

| 40 | 80 | 175 | 405 | 950 | 25 | |

| 40 | 80 | 175 | 405 | 950 | 35 | |

| 39 | 80 | 180 | 470 | 950 | 40 | |

| 40 | 80 | 175 | 405 | 950 | 50 | |

| 37 | 78 | 175 | 355 | 900 | 70 | |

| 28 | 59 | 140 | 305 | 750 | 100 |

Output shaft loads

| PSFN064 | PSFN090 | PSFN110 | PSFN140 | PSFN200 | |

| Radial force for 20000 h | 2150 | 3950 | 4900 | 12000 | 23000 |

| Axial force for 20000 h | 4300 | 8200 | 9500 | 8500 | 16000 |

| Radial force for 30000 h | 1900 | 3500 | 4350 | 11000 | 21000 |

| Axial force for 30000 h | 3800 | 7200 | 8400 | 7500 | 14000 |

| Tilting moment for 20000 h | 132 | 326 | 475 | 1030 | 2445 |

| Tilting moment for 30000 h | 117 | 289 | 422 | 944 | 2232 |

Geometry

| PSFN064 | PSFN090 | PSFN110 | PSFN140 | PSFN200 | P | |

| Pitch circle diameter output shaft | 31.5 | 50 | 63 | 80 | 125 | |

| Centering diameter output flange | 64 | 90 | 110 | 140 | 200 | |

| Flange diameter output | 86 | 118 | 145 | 179 | 247 | |

| Min. total lenght | 71 | 89.5 | 108 | 142 | 172 | 1 |

| 99.5 | 111.5 | 130 | 173 | 217 | 2 | |

| Output flange length |

19.5 |

30 | 29 | 38 | 50 |