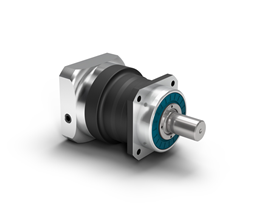

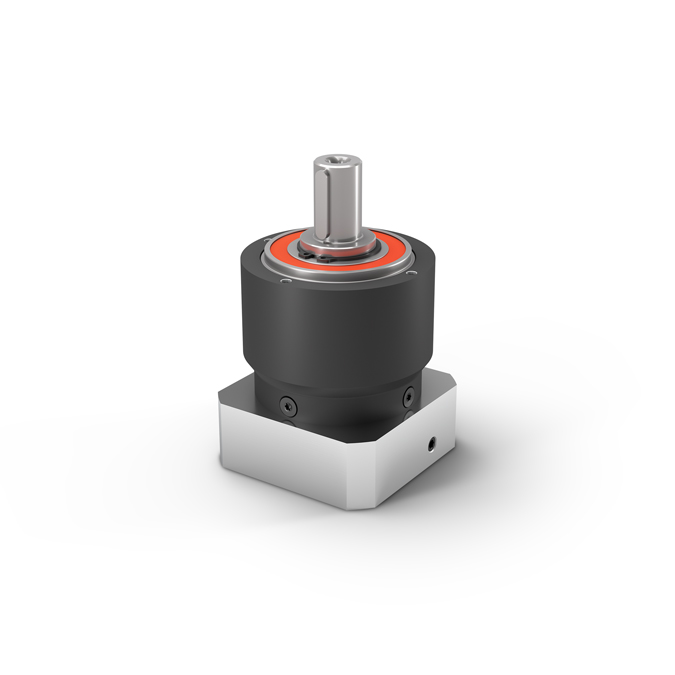

The cost effective planetary gearbox with the best torque-low heat performance.

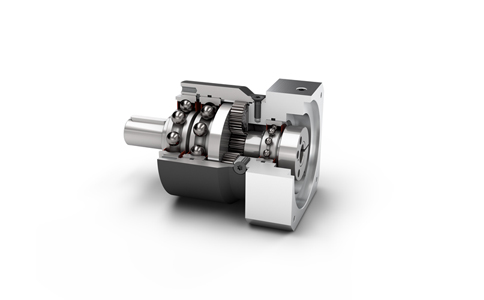

Our PLPE unites the best properties of the Economy Line with a performance advantage. It is cost effective, yet powerful, and generates minimal heat. The optimized output bearing has been designed for high radial and axial forces.

PLPE planetary gearbox is a gearbox that integrates the relevant characteristics of economical products. The performance of PLPE gearbox has also been greatly improved in terms of economical advantages. While this gearbox is economical and practical, the heat generated is high. It is very rare, and the optimized output bearing of this gearbox can withstand high radial and axial forces, and can complete work tasks safely and stably in some difficult jobs.

Product description

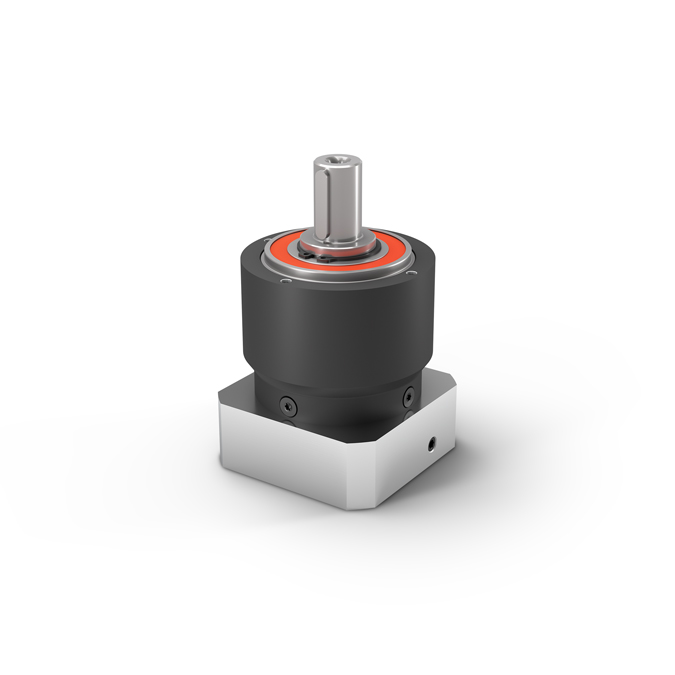

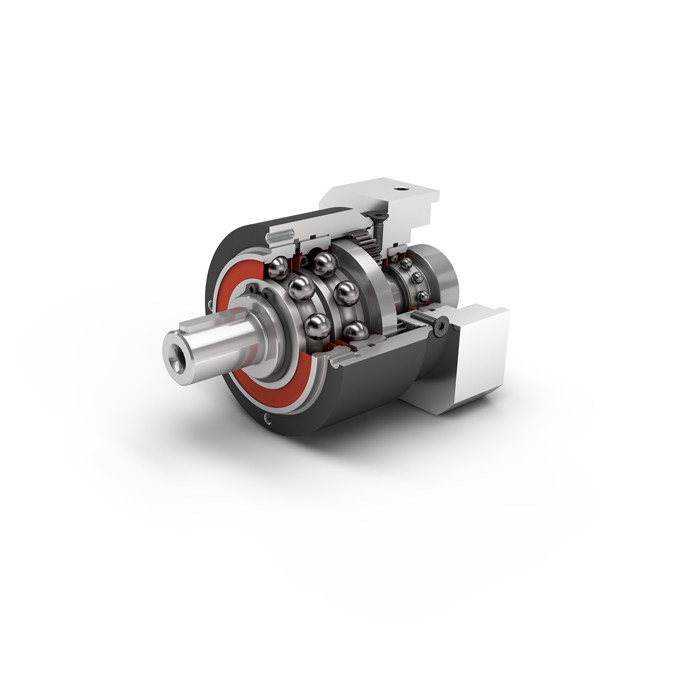

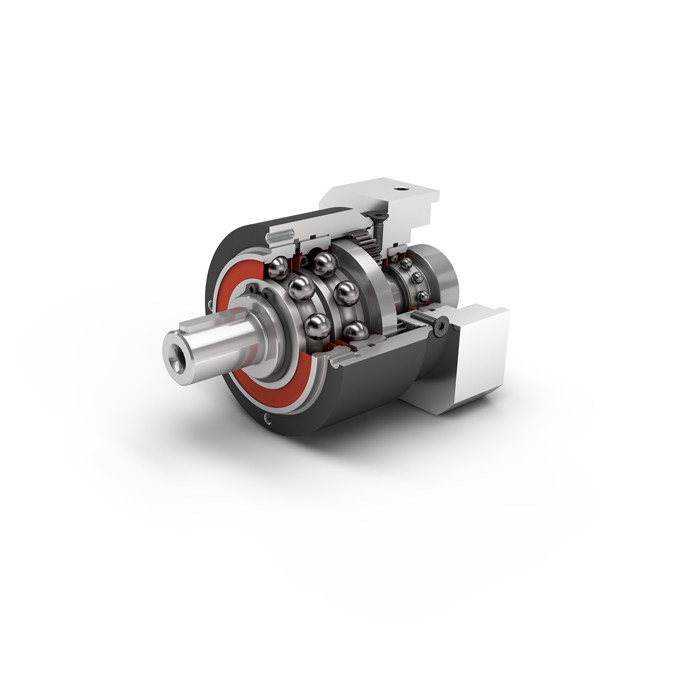

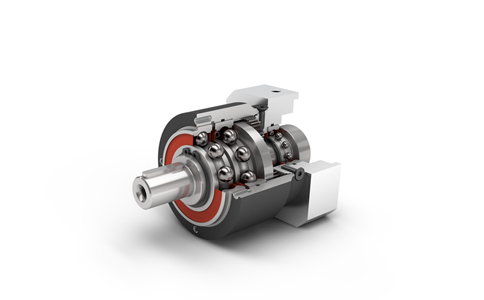

Optimized output bearing of PLPE gearbox. This larger deep groove ball bearing allows PLPE to have high radial and axial forces. No additional bearing assemblies are required, the drive element of this gearbox can be directly mounted on the output shaft, and the structure is simple and very flexible.

Low heat generation at maximum speed. The low friction loss bearing design and lubricated function of this gearbox make PLPE economical and durable. And because of the low heat generation advantage of this gearbox, it can exert its own characteristics even in a high-standard production environment.

This gearbox adopts shaft output and can choose different shaft specifications; two stages of gear planet carrier are available; a total of 17 speed ratio options from 3-100; PLPE structure sizes are 50, 70, 90, 120, 155 Five different specifications; rated torque 5-460Nm, radial force can withstand 800-5200N, axial force can withstand 1000-7000N, return clearance 6-19arcmin (can be customized according to demand). The torsional stiffness of PLPE is 0.7-73Nm, and the weight range is between 0.6-22.5kg. The specific output depends on the product model.

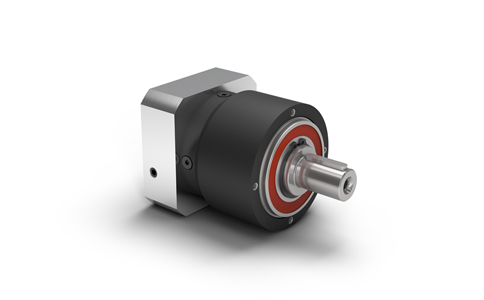

PLPE gearboxs are used in industries such as food, printing and cutting machines or where high radial and axial forces are required.

Product advantages

Strong performance, high radial and axial forces, economical, low heat generation

Optional

Various types of output shafts

lubricating

Optimized tensioning system

Various types of drive flanges

Use

Food industry, pharmaceutical technology and pharmaceutical industry, printing industry

Features

Cost-effective

Low heat at high speed

Optimized output bearing

Can be installed anywhere

Lifetime lubrication maintenance free

Precise engagement

PLPE planetary gearbox speed ratio model

PLPE50-3、PLPE50-4、PLPE50-5、PLPE50-7、PLPE50-8、PLPE50-10、PLPE50-9、PLPE50-12、PLPE50-15、PLPE50-16、PLPE50-20、PLPE50-25、PLPE50-32、PLPE50-40、PLPE50-64、PLPE50-100

PLPE70-3、PLPE70-4、PLPE70-5、PLPE70-7、PLPE70-8、PLPE70-10、PLPE70-9、PLPE70-12、PLPE70-15、PLPE70-16、PLPE70-20、PLPE70-25、PLPE70-32、PLPE70-40、PLPE70-64、PLPE70-100

PLPE90-3、PLPE90-4、PLPE90-5、PLPE90-7、PLPE90-8、PLPE90-10、PLPE90-9、PLPE90-12、PLPE90-15、PLPE90-16、PLPE90-20、PLPE90-25、PLPE90-32、PLPE90-40、PLPE90-64、PLPE90-100

PLPE120-3、PLPE120-4、PLPE120-5、PLPE120-7、PLPE120-8、PLPE120-10、PLPE120-9、PLPE120-12、PLPE120-15、PLPE120-16、PLPE120-20、PLPE120-25、PLPE120-32、PLPE120-40、PLPE120-64、PLPE120-100

PLPE155-4、PLPE155-5、PLPE155-10、PLPE155-16、PLPE155-20、PLPE155-25、PLPE155-40、PLPE155-50、PLPE155-100

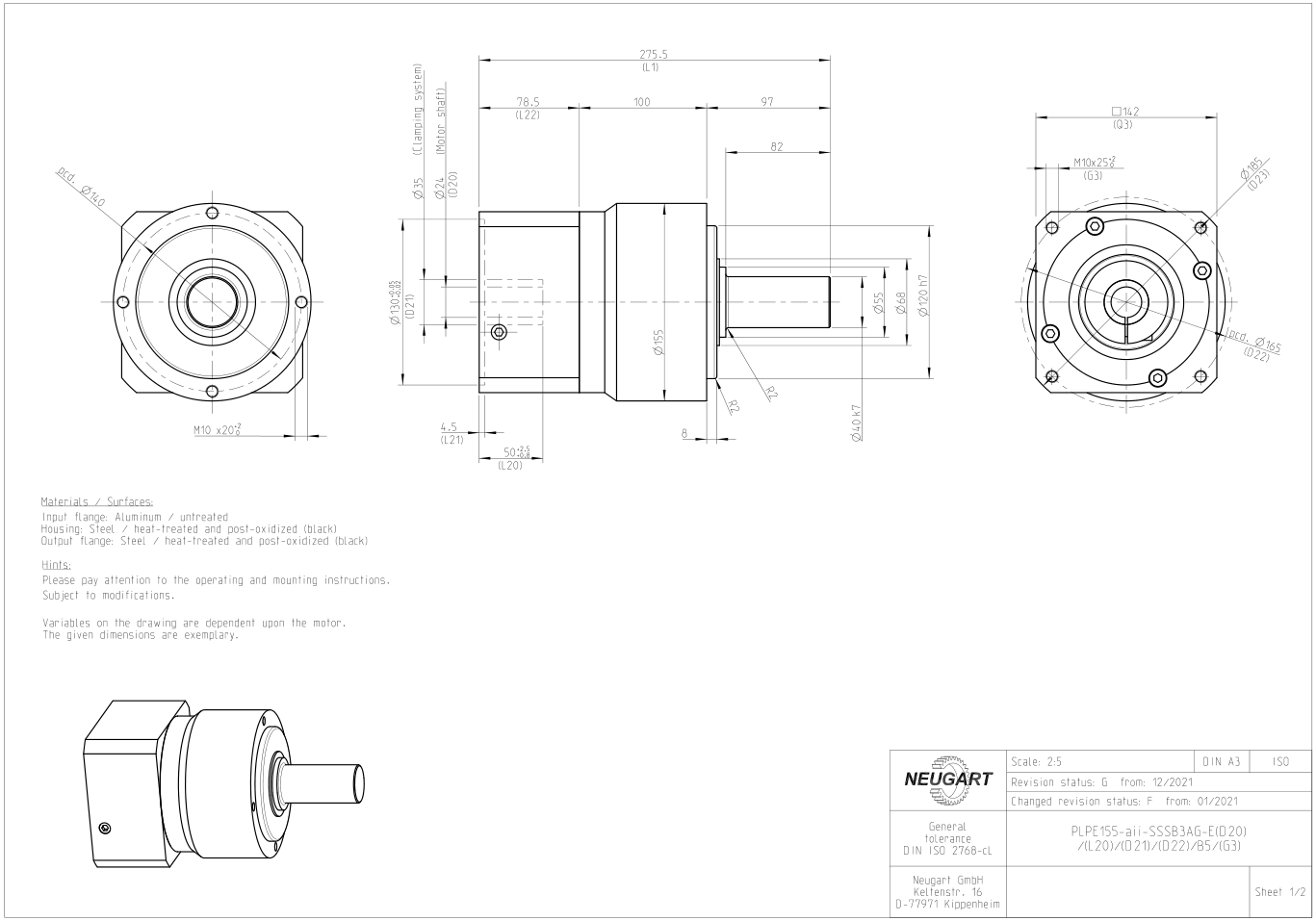

PLPE internal structure dimension drawing:

| Gearbox characteristics | PLPE050 | PLPE070 | PLPE090 | PLPE120 | PLPE155 | P | |

|

Reduer |

3, 4, 5, 7, 8, 10 | 1 | |||||

| 9, 12, 15, 16, 20, 25, 32, 40, 50,64,100 | 2 | ||||||

| Service life | h | 30.000 | |||||

|

Efficiency at full load |

% |

98 | |||||

| 97 | |||||||

| ℃ | -25/90 | ||||||

| Protection class |

IP54 |

||||||

| Standard lubrication | Grease (lifetime lubrication) | ||||||

| Food grade lubrication | Grease (lifetime lubrication) | ||||||

| Low temperature lubrication | Grease (lifetime lubrication) | ||||||

| Lnstallation location | Any | ||||||

| Standard return clearance | arcmin | <15-<19 | <10-<12 | <7-<9 | <7-<9 | <6-<9 | |

| Torsional stiffness | Nm/arcmin | 0.7-1.1 | 3.5-5.8 | 9.7-16.1 | 24.5-43.5 | 54.5-73.0 | |

| Reducer weight | kg | 0.6-1.1 | 1.4-1.9 | 3.2-4.0 | 7.4-9.6 | 16.8-22.5 | |

| Standard case surface | Housing: Steel - heat-treated and post-oxidized(black) | ||||||

| Running noise | dB/(A) | 58 | 58 | 60 | 65 | 70 | |

| Max bending moment based on the gearbox input flange | Nm | 3 | 8 | 16 | 40 | 180 | |

Nominal output torque

| PLPE050 | PLPE070 | PLPE090 | PLPE120 | PLPE155 | I | P |

| 11 | 28 | 85 | 115 | - | 3 | 1 |

| 15 | 33 | 90 | 155 | 460 | 4 | |

| 13 | 30 | 82 | 172 | 445 | 5 | |

| 8.5 | 25 | 65 | 135 | - | 7 | |

| 6 | 18 | 50 | 120 | - | 8 | |

| 5 | 15 | 38 | 95 | 210 | 10 | |

| 12 | 33 | 97 | 157 | - | 9 | 2 |

| 15 | 33 | 90 | 195 | - | 12 | |

| 13 | 33 | 82 | 172 | - | 15 | |

| 15 | 33 | 90 | 195 | 460 | 16 | |

| 15 | 33 | 90 | 195 | 460 | 20 | |

| 13 | 30 | 82 | 172 | 445 | 25 | |

| 15 | 33 | 90 | 195 | - | 32 | |

| 13 | 30 | 82 | 172 | 460 | 40 | |

| - | - | - | - | 445 | 50 | |

| 7.5 | 18 | 50 | 120 | - | 64 | |

| 5 | 15 |

38 |

95 | 210 | 100 |

Output shaft loads

| PLPE050 | PLPE070 | PLPE090 | PLPE120 | PLPE155 | ||

| Radial force for 20000 h | N | 800 | 1050 | 1900 | 2500 | 5200 |

| Axial force for 20000 h | N | 1000 | 1350 | 2000 | 4000 | 7000 |

| Radial force for 30000 h | N | 700 | 900 | 1700 | 2150 | 4600 |

| Axial force for 30000 h | N | 800 | 1000 | 1500 | 3000 | 6000 |

| Tilting moment for 20000 h | Nm | 26 | 42 | 99 | 168 | 497 |

| Tilting moment for 30000 h | Nm | 22 | 36 | 89 | 144 | 440 |

Geometry

| PLPE050 | PLPE070 | PLPE090 | PLPE120 | PLPE155 | P | ||

| Shaft diameter output | mm | 12 | 16 | 22 | 32 | 40 | |

| Centering diameter output | mm |

35 |

52 | 68 | 90 | 120 | |

| Housing diameter | mm | 50 | 70 | 90 | 120 | 155 | |

| Min. total lenght | mm | 94 | 111 | 147 | 192 | 275.5 | 1 |

| mm | 106.5 | 124 | 165 | 219.5 | 320 | 2 | |

| Shaft lenght output | mm | 24.5 | 36 | 46 | 68 | 97 |