The highest dynamics in multiple axis systems

Unrivaled price-performance ratio

Low heat generation at highest speeds

For any mounting position

Lifetime lubrication for maintenance-free operation

Precise gearing

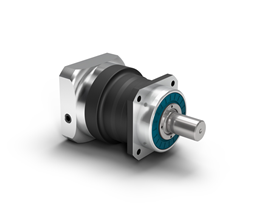

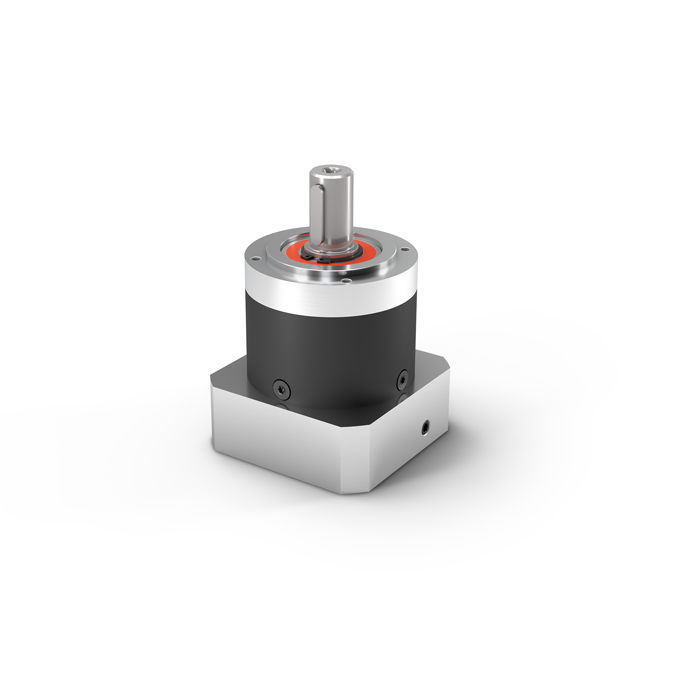

PLE gearbox model:

PLE40, PLE60, PLE80, PLE120, PLE160

PLE gearbox speed ratio

First gear ratio: 3, 4, 5, 7, 8, 10

Secondary speed ratio: 9, 12, 15, 16, 20, 25, 32, 40, 64

Three-stage speed ratio: 60, 80, 100, 120, 160, 200, 256, 320, 512

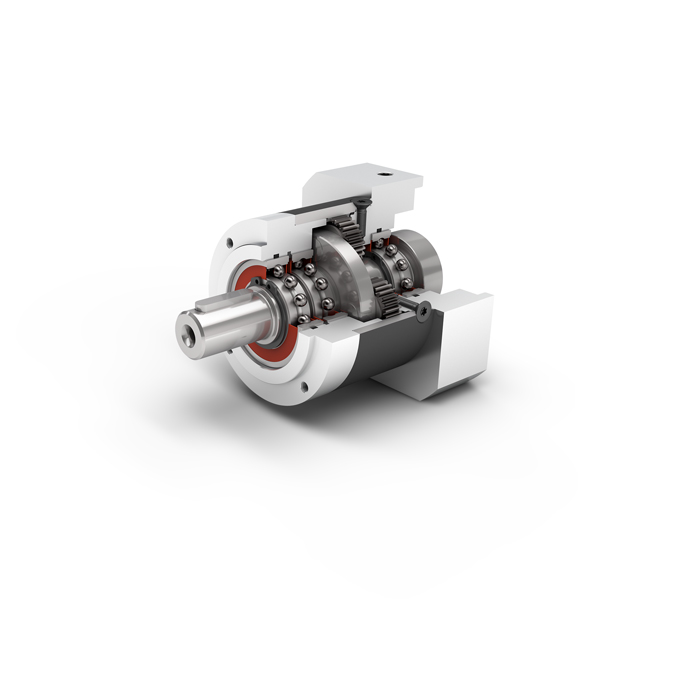

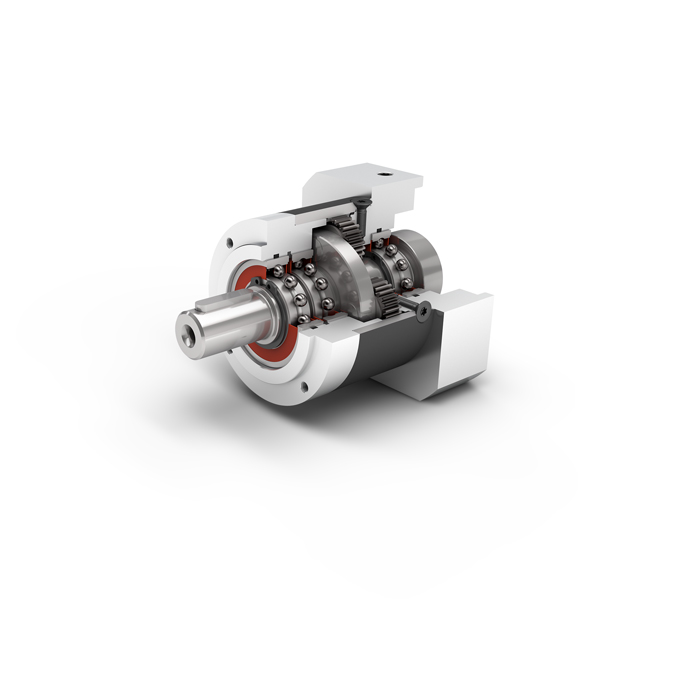

PLE planetary gearbox is a basic gearbox among NEUGART gearboxs, and it is also widely used. PLE has the characteristics of light weight and strong performance. And because of the low friction loss bearing design of this gearbox, it is very suitable for operation in high standard production conditions. Compared with other gearboxs, high efficiency can also be achieved at high speeds.

This gearbox has five sizes of PLE40, PLE60, PLE80, PLE120 and PLE160 to choose from, and the NEUGART series can also choose a small size gearbox. With 3 sets of planetary gear carriers, there are 24 speed ratios from 3-512 to choose from, which are suitable for different types of servo motors and stepper motors.

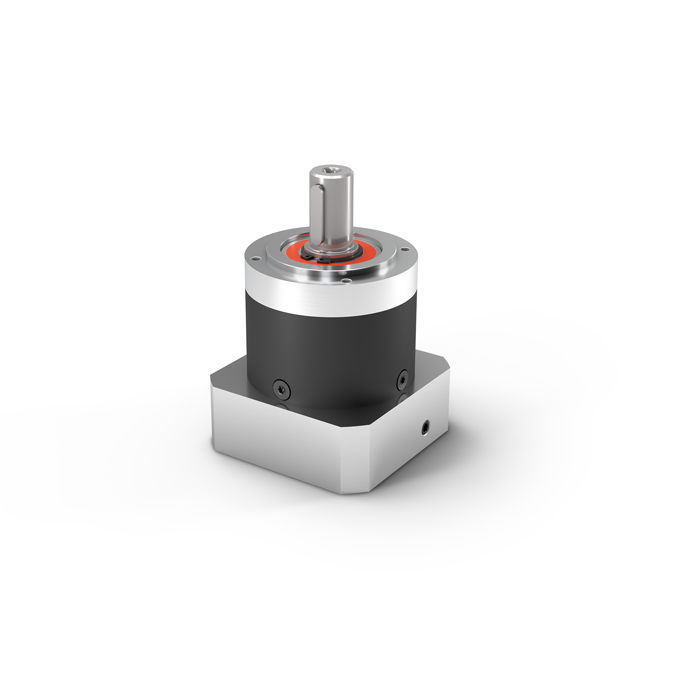

PLE is an economical gearbox with a circular output flange and an output shaft. The specifications of the output shaft can be selected (see the NEUGART selection catalog for details). It is a coaxial gearbox with a compact structure, high bearing capacity, Long life, low noise and other advantages, the planetary gear carrier adopts spur gears, low friction deep groove ball bearings, etc. The components are relatively simple and have far-reaching significance for the NEUGART gearbox series.

This one can work between -25°C and 90°C; IP54 protection grade; standard lubrication, low temperature lubrication and food grade lubrication, a total of three lubrication methods can be selected; because of its compact structure, any installation method can be used, Easy to install; the torsional stiffness is within the range of 0.7-75Nm, and the specific model has different data to choose from; the weight range of the gearbox is at least 0.3-23.7Kg, which can be selected. The series data such as the weight load of this gearbox are recorded in detail in the selection sample, and the specific model selection is determined according to the motor parameters and load conditions.

PLE planetary gearboxs are widely used in automation, machine tools, food, laser cutting, truss, packaging machinery and other industries. Shenzhen Weidong Automation provides a full range of NEUGART products, professional technology provides all-round technical support, NCP selection software, quick quotation, etc.

| Gearbox characteristics | PLE040 | PLE060 | PLE080 | PLE120 | PLE160 | P | |

| service life | h | 30.000 | |||||

| Efficiency at full load | % | 98/97/92 | |||||

| Min operating temperature/max operating temperature | ℃ | -25/90 | |||||

| Protection class |

IP54 |

||||||

| Standard lubrication | Grease (lifetime lubrication) | ||||||

| food grade lubrication | Grease (lifetime lubrication) | ||||||

| low temperature lubrication | Grease (lifetime lubrication) | ||||||

| Installation location | Any | ||||||

|

Standard return clearance |

arcmin |

<15 | <10 | <7 | <7 | <6 | 1 |

| <19 | <12 | <9 | <9 | <9 | 2 | ||

| <22 | <15 | <11 | <11 | - | 3 | ||

|

Torsional stiffness |

Nm/arcmin |

0.7-1.0 | 2.1-2.8 | 7.2-10.0 | 15.5-21.0 | 57.5-69.0 | 1 |

| 0.8-1.0 | 2.3-2.8 | 7.9-10.4 | 17.5-22.0 | 61.0-75.0 | 2 | ||

| 0.8-1.0 | 2.3-2.8 | 7.9-10.5 | 17.5-22.0 | - | 3 | ||

|

Reducer weight |

kg | 0.3-0.4 | 0.9 | 2.1 | 5.6-5.7 | 17.4-17.6 | 1 |

| kg | 0.4-0.5 | 1.1 | 2.6 | 7.3-7.5 | 23.5-23.7 | 2 | |

| kg | 0.5 | 1.3 | 3.1 | 9.2-9.4 | - | 3 | |

| Standard case surface | Housing: Steel - heat-treated and post-oxidized(black) | ||||||

| running noise | dB/(A) | 58 | 58 | 60 | 65 | 70 | |

| Max bending moment based on the gearbox input flange | Nm | 3 | 8 | 16 | 40 | 140 | |

Nominal output torque

| PLE040 | PLE060 | PLE080 | PLE120 | PLE160 | I | P |

| 11 | 28 | 85 | 115 | 400 | 3 | 1 |

| 15 | 38 | 115 | 155 | 450 | 4 | |

| 14 | 40 | 110 | 195 | 450 | 5 | |

| 8.5 | 25 | 65 | 135 | - | 7 | |

| 6 | 18 | 50 | 120 | 450 | 8 | |

| 5 | 15 | 38 | 95 | - | 10 | |

| 16.5 | 44 | 130 | 210 | - | 9 |

2 |

| 20 | 44 | 120 | 260 | 800 | 12 | |

|

18 |

44 | 110 | 230 | 700 | 15 | |

| 20 | 44 | 120 | 260 | 800 | 16 | |

| 20 | 44 | 120 | 260 | 800 | 20 | |

| 18 | 40 | 110 | 230 | 700 | 25 | |

| 20 | 44 | 120 | 260 | 800 | 32 | |

| 18 | 40 | 110 | 230 | 700 | 40 | |

| 7.5 | 18 | 50 | 120 | 450 | 64 | |

| 20 | 44 | 110 | 260 | - | 60 |

3 |

| 20 | 44 | 120 | 260 | - | 80 | |

| 20 | 44 | 120 | 260 | - | 100 | |

| 18 | 44 | 110 | 230 | - | 120 | |

| 20 | 44 | 120 | 260 | - | 160 | |

| 18 | 40 | 110 | 230 | - | 200 | |

| 20 | 44 | 120 | 260 | - | 256 | |

| 18 | 40 | 110 | 230 | - | 320 | |

| 7.5 | 18 | 50 | 120 | - |

512 |

Output shaft loads

| PLE040 | PLE060 | PLE080 | PLE120 | PLE160 | |

| Radial force for 20000 h |

200 |

400 | 750 | 1750 | 5000 |

| Axial force for 20000 h | 200 | 500 | 1000 | 2500 | 7000 |

| Radial force for 30000 h | 160 | 340 | 650 | 1500 | 4200 |

| Axial force for 30000 h | 160 | 450 | 900 | 2100 | 6000 |

| Tilting moment for 20000 h | 5 | 14 | 31 | 101 | 474 |

| Tilting moment for 30000 h | 4 | 12 | 27 | 86 |

398 |

Geometry

| PLE040 | PLE060 | PLE080 | PLE120 | PLE160 | ||

| Pitch circle diameter output | 34 | 52 | 70 | 100 | 145 | |

| Shaft diameter output | 10 | 14 | 20 | 25 | 40 | |

| Centering diameter output | 26 | 40 | 60 | 80 | 130 | |

| Housing length | 40 | 60 | 80 | 115 | 160 | |

| Min. total lenght | 88.5 | 106 | 133.5 | 176.5 | 255.5 | 1 |

| 106.5 | 118.5 | 150.5 | 204 | 305 | 2 | |

| 114 | 131 | 168 | 231.5 | - | 3 | |

| Shaft lenght output | 26 | 35 | 40 | 55 | 87 |