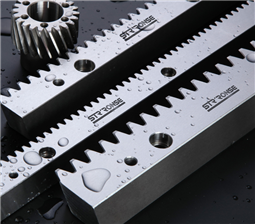

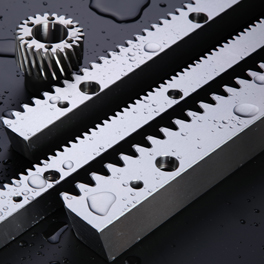

Grinding Rack: Rack drive is a very efficient transmission method and is usually used in applications with large axial forces. The advantage is that the drive unit maintains the same stiffness over the entire stroke length; in addition, it is very economical for applications with strokes over 2m.

The rack and pinion drive is mainly driven by the back and forth rotation of the gear. In principle, the racks are divided into two forms: straight racks and helical racks, the standard part is 1m, and multiple racks can be spliced in any length.

The rack can be milled or ground according to customer requirements, and the rack can be processed by different processes, and the hardness will be different. According to the actual load situation, the rack drive selection scheme can be provided.

The industry standard specification modules of M1.5--M8, whether straight or helical, have sufficient stock in stock. High-precision racks reach DIN6 accuracy, pitch error is less than 0.032mm/m, widely used in many fields, including transmission shafts, mobile gantry, handling manipulators, material handling, automation, automotive, aviation, robotics, CNC machine tools and materials transport system, etc.

1. Introduction of precision grinding rack:

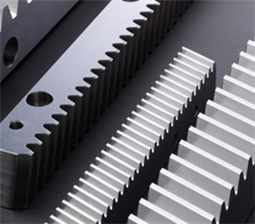

Complete tooth profile: straight and helical.

2. Complete specifications: module 1.5~8, rack can be spliced (installation block auxiliary installation). Single processing length can choose 1000mm and 500mm.

3. Material: C45 carbon steel

4. Multiple processes: heat treatment / no heat treatment, grinding / no grinding, tooth surface grinding / no tooth surface grinding.

5. Can be produced according to customer requirements. Germany imported production machinery, standard assembly line operation, excellent precision and carrying capacity, and provide fast delivery and preferential prices.

Second, the main characteristics of the grinding rack:

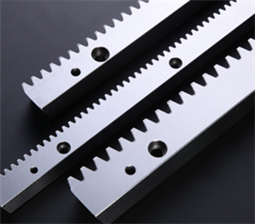

Zero backlash/high accuracy.

The meshing between the gear and the rack can ensure that more than two teeth are always in contact, with a positioning accuracy of ±0.02mm, and the accumulated error between the tooth pitches can be eliminated with high precision.

The rack-and-pinion transmission system can achieve high-speed operation, and is used in conjunction with the motor and planetary reducer, which will not generate heat or wear parts at high speeds.

The modular design of the grinding rack ensures quality and precision. The standard lengths of 1m and 0.5m can be spliced for use, or a shorter length can be cut as needed, which is conducive to rack storage, cost reduction and interchange. The grinding rack has a professional mounting block for auxiliary installation, which will not affect the overall accuracy. The accuracy of the rack is accurately transmitted to the next rack through the teeth of the mounting block.

Note: Non-standard parts can be customized according to the situation

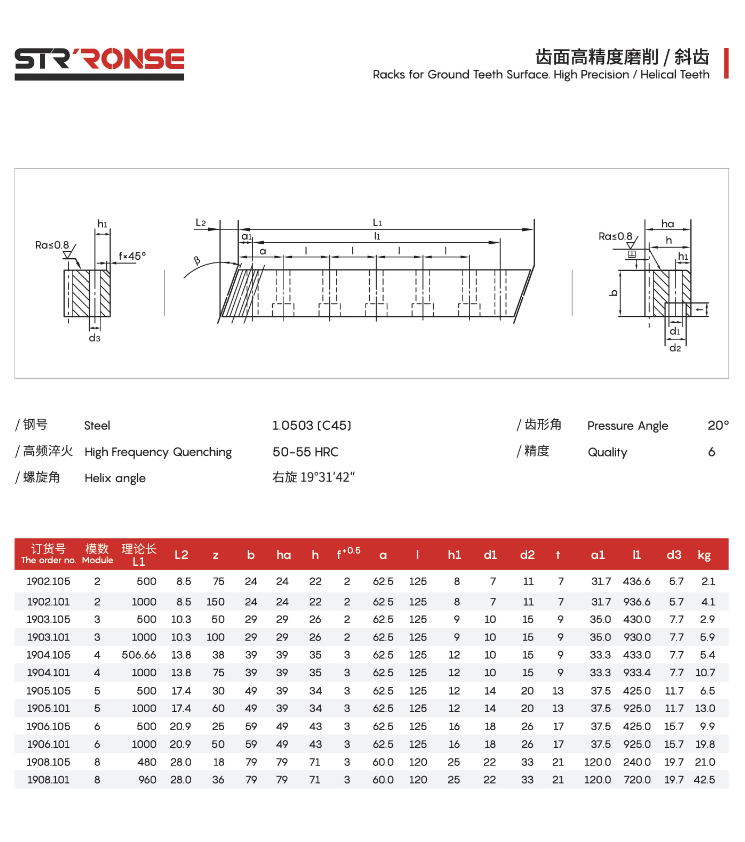

Grinding helical rack parameters

| The order no. | Module | L1 | L2 | z | b | ha | h | f+0.5 | a | I | h1 | d1 | d2 | t | a1 | l1 | d3 | kg |

| 1902.105 | 2 | 500 | 8.5 | 75 | 24 | 24 | 22 | 2 | 62.5 | 125 | 8 | 7 | 11 | 7 | 31.7 | 436.6 | 5.7 | 2.1 |

| 1902.101 | 2 | 1000 | 8.5 | 150 | 24 | 24 | 22 | 2 | 62.5 | 125 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 | 4.1 |

| 1903.105 | 3 | 500 | 10.3 | 50 | 29 | 29 | 26 | 2 |

62.5 |

125 | 9 | 10 | 15 | 9 | 35 | 430 | 7.7 | 2.9 |

| 1903.101 | 3 | 1000 | 10.3 | 100 | 29 | 29 | 26 | 2 | 62.5 | 125 | 9 | 10 | 15 | 9 | 35 | 930 | 7.7 | 5.9 |

| 1904.105 | 4 | 506.66 | 13.8 | 38 | 39 | 39 | 35 | 3 | 62.5 | 125 | 12 | 10 | 15 | 9 | 33.3 | 433 | 7.7 | 5.4 |

| 1904.101 | 4 | 1000 | 13.8 | 75 | 39 | 39 |

35 |

3 |

62.5 |

125 | 12 | 10 | 15 | 9 | 33.3 | 933.4 | 7.7 | 10.7 |

| 1905.105 | 5 | 500 | 17.4 | 30 | 49 | 39 | 34 | 3 | 62.5 | 125 | 12 | 14 | 20 | 13 | 37.5 | 425 | 11.7 | 6.5 |

| 1905.101 | 5 | 1000 | 17.4 | 60 | 49 | 39 | 34 | 3 | 62.5 | 125 | 12 | 14 | 20 | 13 | 37.5 | 925 | 11.7 | 13 |

| 1906.105 | 6 | 500 | 20.9 | 25 | 59 | 49 | 43 | 3 | 62.5 | 125 | 16 | 18 | 26 | 17 | 37.5 | 425 | 15.7 | 9.9 |

| 1906.101 | 6 | 1000 | 20.9 | 50 | 59 | 49 | 43 | 3 | 62.5 | 125 | 16 | 18 | 26 | 17 | 37.5 | 925 | 15.7 | 19.8 |

| 1908.105 | 8 | 480 | 28 | 18 | 79 | 79 | 71 | 3 | 60 | 120 | 25 | 22 | 33 | 21 | 120 | 240 | 19.7 | 21 |

| 1908.101 | 8 | 960 | 28 | 36 | 79 | 79 | 71 | 3 | 60 | 120 | 25 | 22 | 33 | 21 | 120 | 720 | 19.7 | 42.5 |

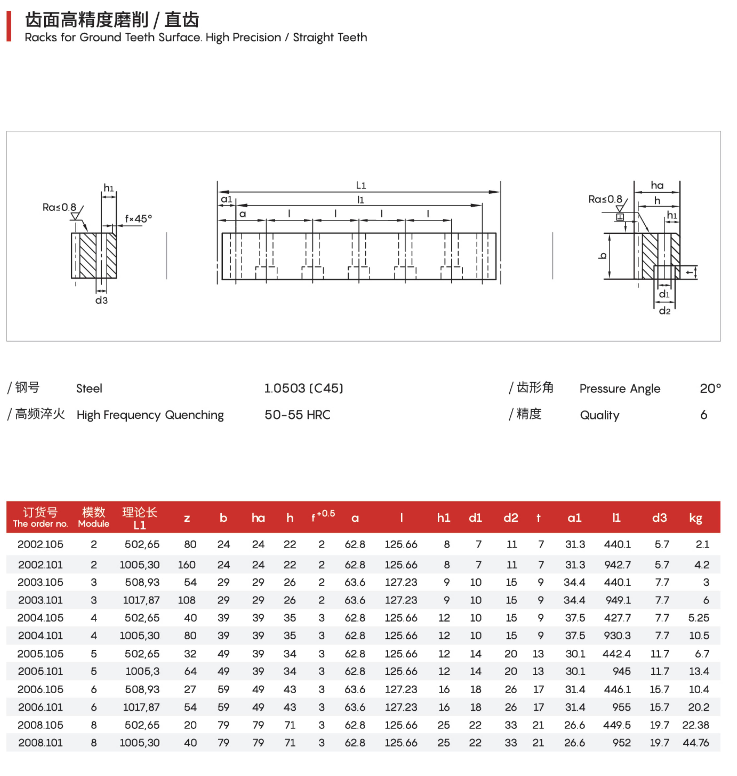

| order no | Module | L1 | z | b | ha | h | f+0.5 | a | l | h1 | d1 | d2 | t | a1 | l1 | d3 | kg |

| 2002.105 | 2 | 502.65 | 80 | 24 | 24 | 22 | 2 | 62.8 | 125.66 | 8 | 7 | 11 | 7 | 31.3 | 440.1 | 5.7 | 2.1 |

| 2002.101 | 2 | 1005.3 | 160 | 24 | 24 | 22 | 2 | 62.8 | 125.66 | 8 | 7 | 11 | 7 | 31.3 | 942.7 | 5.7 | 4.2 |

| 2003.105 | 3 | 508.93 | 54 | 29 | 29 | 26 | 2 | 63.6 | 127.23 | 9 | 10 | 15 | 9 | 34.4 | 440.1 | 7.7 | 3 |

| 2003.101 | 3 | 1017.87 | 108 | 29 | 29 | 26 | 2 | 63.6 | 127.23 | 9 | 10 | 15 | 9 | 34.4 | 949.1 | 7.7 | 6 |

| 2004.105 | 4 | 502.65 | 40 | 39 | 39 | 35 | 3 | 62.8 |

125.66 |

12 | 10 | 15 | 9 | 37.5 | 427.7 | 7.7 | 5.25 |

| 2004.101 | 4 | 1005.3 | 80 | 39 | 39 | 35 | 3 | 62.8 | 125.66 | 12 | 10 | 15 | 9 | 37.5 | 930.3 | 7.7 | 10.5 |

| 2005.105 | 5 | 502.65 | 32 | 49 | 39 | 34 | 3 | 62.8 | 125.66 | 12 | 14 | 20 | 13 | 30.1 | 442.4 | 11.7 | 6.7 |

| 2005.101 | 5 | 1005.3 | 64 | 49 | 39 | 34 | 3 | 62.8 | 125.66 | 12 | 14 | 20 | 13 | 30.1 | 945 | 11.7 | 13.4 |

| 2006.105 | 6 | 508.93 | 27 | 59 | 49 | 43 | 3 | 63.6 | 127.23 | 16 | 18 | 26 | 17 | 31.4 | 446.1 | 15.7 | 10.4 |

| 2006.101 | 6 | 1017.87 | 54 | 59 | 49 | 43 | 3 | 63.6 | 127.23 | 16 | 18 | 26 | 17 | 31.4 | 955 | 15.7 | 20.2 |

| 2008.105 | 8 | 502.65 | 20 | 79 | 79 | 71 | 3 | 62.8 | 125.66 | 25 | 22 | 33 | 21 | 26.6 | 449.5 | 19.7 | 22.38 |

| 2008.101 | 8 | 1005.3 | 40 | 79 | 79 | 71 | 3 | 62.8 | 125.66 | 25 | 22 | 33 | 21 | 26.6 | 952 | 19.7 | 44.76 |