product description

The grinding rack and pinion are processed by grinding the tooth surface after quenching, which has the advantages of low transmission noise, high transmission technical efficiency and long service life. The most common material we use in the production process of gear grinding is steel, and the steel includes quenched and tempered steel, hardened steel, carburized surface hardened steel and nitrided steel. Grinding is an effective tooth profile finishing method, usually used to machine hard tooth surfaces. It has a strong ability to correct the errors before grinding, and can achieve high precision.

1. The accumulative error of the grinding level accuracy of the grinding rack is 0.015mm/300mm (any 300mm);

2. With straight tooth/helical tooth type, it can adapt to various conditions of use;

3. With heat treatment type/non-heat treatment type, the same modulus can have multiple strengths;

4. It has a square/circular appearance and is easy to integrate and use;

5. The modulus is 1.5~8, which can be connected/interchanged at will, and the stroke can be extended infinitely;

6. Overall pitch line error ≤00.032mm;

7. Relevant selection schemes and rack inspection reports can be provided.

Application field

Used in automated robots, gantry machining centers, laser cutting machines, aluminum profiles, woodworking machining centers, truss seventh axis and other fields. Such racks generally require high precision, accurate positioning and stable operation.

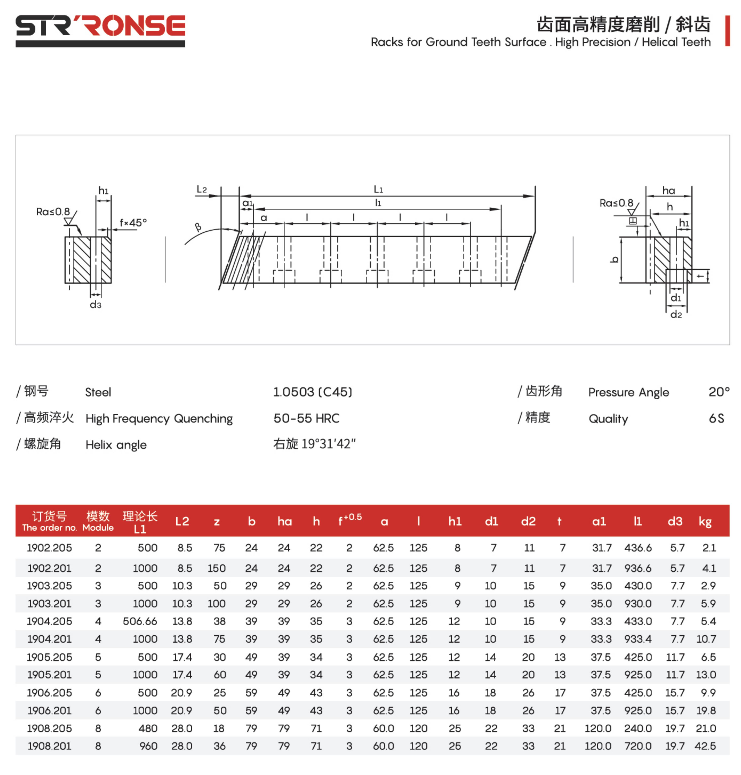

| order no. | Module | L | L2 | z | b | ha | h | f+0.5 | a | l | h1 | d1 | d2 | t | a1 | l1 | d3 | kg |

| 1902.205 | 2 | 500 | 8.5 |

75 |

24 | 24 | 22 | 2 | 62.5 | 125 | 8 | 7 |

11 |

7 | 31.7 | 436.6 | 5.7 | 2.1 |

| 1902.201 | 2 | 1000 | 8.5 | 150 | 24 | 24 | 22 | 2 | 62.5 | 125 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 | 4.1 |

| 1903.205 | 3 | 500 | 10.3 | 50 | 29 | 29 | 26 | 2 | 62.5 | 125 | 9 | 10 | 15 | 9 | 35 | 430 | 7.7 | 2.9 |

| 1903.201 | 3 | 1000 | 10.3 | 100 | 29 | 29 | 26 | 2 | 62.5 | 125 | 9 | 10 | 15 | 9 | 35 | 930 | 7.7 | 5.9 |

| 1904.205 | 4 | 506.66 |

13.8 |

38 | 39 | 39 | 35 | 3 | 62.5 | 125 | 12 | 10 | 15 | 9 | 33.3 | 433 | 7.7 | 5.4 |

| 1904.201 | 4 | 1000 | 13.8 | 75 | 39 | 39 | 35 | 3 | 62.5 |

125 |

12 | 10 | 15 | 9 | 33.3 | 933.4 | 7.7 | 10.7 |

| 1905.205 | 5 | 500 | 17.4 | 30 | 49 | 39 | 34 | 3 | 62.5 | 125 | 12 | 14 | 20 | 13 | 37.5 | 425 | 11.7 | 6.5 |

| 1905.201 | 5 | 1000 | 17.4 | 60 | 49 | 39 | 34 | 3 | 62.5 | 125 | 12 | 14 | 20 | 13 | 37.5 | 925 | 11.7 | 13 |

| 1906.205 | 6 | 500 | 20.9 | 25 | 59 | 49 | 43 | 3 | 62.5 | 125 | 16 | 18 | 26 | 17 | 37.5 | 425 | 15.7 | 9.9 |

| 1906.201 | 6 | 1000 | 20.9 | 50 | 59 | 49 | 43 | 3 | 62.5 | 125 | 16 | 18 | 26 | 17 | 37.5 | 925 | 15.7 | 19.8 |

| 1908.205 | 8 | 480 | 28 | 18 | 79 | 79 | 71 | 3 | 60 | 120 | 25 | 22 | 33 | 21 | 120 | 240 | 19.7 | 21 |

| 1908.201 | 8 | 960 | 28 | 36 | 79 | 79 | 71 | 3 | 60 | 120 | 25 | 22 | 33 | 21 | 120 | 720 | 19.7 | 42.5 |

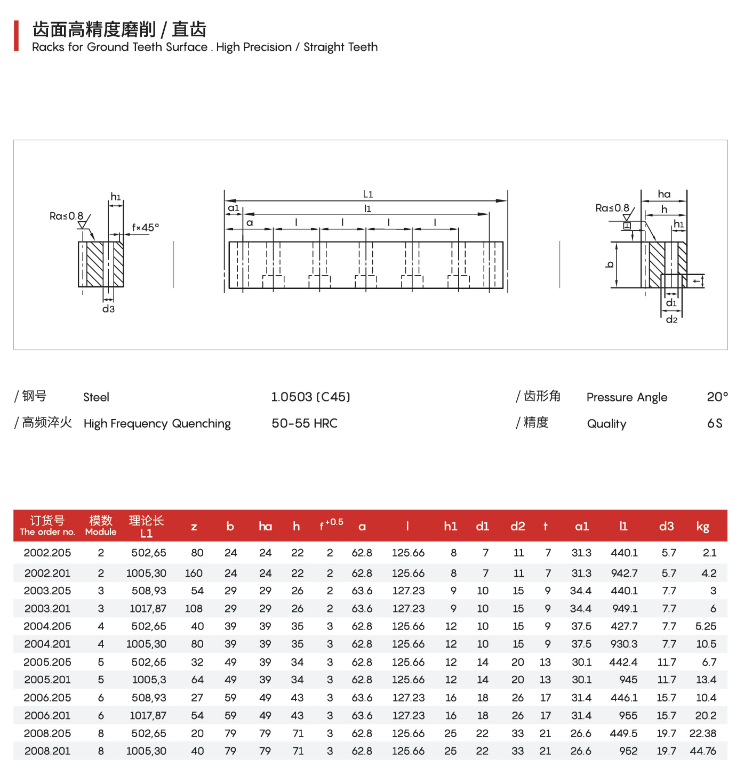

| order no. | Module | L | z | b | ha |

h |

f+0.5 | a | l | h1 | d1 | d2 | t | a1 | l1 | d3 | kg |

| 2002.205 | 2 | 502.65 | 80 | 24 | 24 | 22 | 2 | 62.8 | 125.66 | 8 | 7 | 11 | 7 | 31.3 | 440.1 | 5.7 | 2.1 |

| 2002.201 | 2 | 1005.3 | 160 | 24 | 24 | 22 | 2 | 62.8 | 125.66 | 8 | 7 | 11 | 7 | 31.3 | 942.7 | 5.7 | 4.2 |

|

2003 .205 |

3 | 508.93 | 54 | 29 | 29 | 26 | 2 | 63.6 | 127.23 | 9 | 10 | 15 | 9 | 34.4 | 440.1 | 7.7 | 3 |

| 2003.201 | 3 | 1017.87 | 108 | 29 | 29 | 26 | 2 | 63.6 | 127.23 | 9 | 10 | 15 | 9 | 34.4 | 949.1 | 7.7 | 6 |

| 2004.205 | 4 | 502.65 | 40 | 39 | 39 | 35 | 3 | 62.8 | 125.66 | 12 | 10 | 15 | 9 | 37.5 | 427.7 | 7.7 | 5.25 |

| 2004.201 | 4 | 1005.3 | 80 | 39 | 39 | 35 | 3 | 62.8 | 125.66 | 12 | 10 | 15 | 9 | 37.5 | 930.3 | 7.7 | 10.5 |

| 2005.205 | 5 | 502.65 | 32 | 49 | 39 | 34 | 3 | 62.8 | 125.66 | 12 | 14 | 20 | 13 | 30.1 | 442.4 | 11.7 | 6.7 |

| 2005.201 | 5 | 1005.3 | 64 | 49 | 39 | 34 | 3 | 62.8 | 125.66 | 12 | 14 | 20 | 13 | 30.1 | 945 | 11.7 | 13.4 |

| 2006.205 | 6 | 508.93 | 27 | 59 | 49 | 43 | 3 | 63.6 | 127.23 | 16 | 18 | 26 | 17 | 31.4 | 446.1 | 15.7 | 10.4 |

| 2006.201 | 6 | 1017.87 | 54 | 59 | 49 | 43 | 3 | 63.6 | 127.23 | 16 | 18 | 26 | 17 | 31.4 | 955 | 15.7 | 20.2 |

| 2008.205 | 8 | 502.65 | 20 | 79 | 79 | 71 | 3 | 62.8 | 125.66 | 25 | 22 | 33 | 21 | 26.6 | 449.5 | 19.7 | 22.38 |

| 2008.201 | 8 | 1005.3 | 40 | 79 | 79 | 71 | 3 | 62.8 | 125.66 | 25 | 22 | 33 | 21 | 26.6 | 952 | 19.7 | 44.76 |