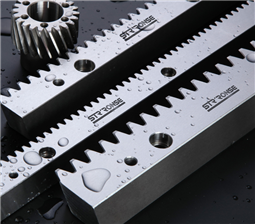

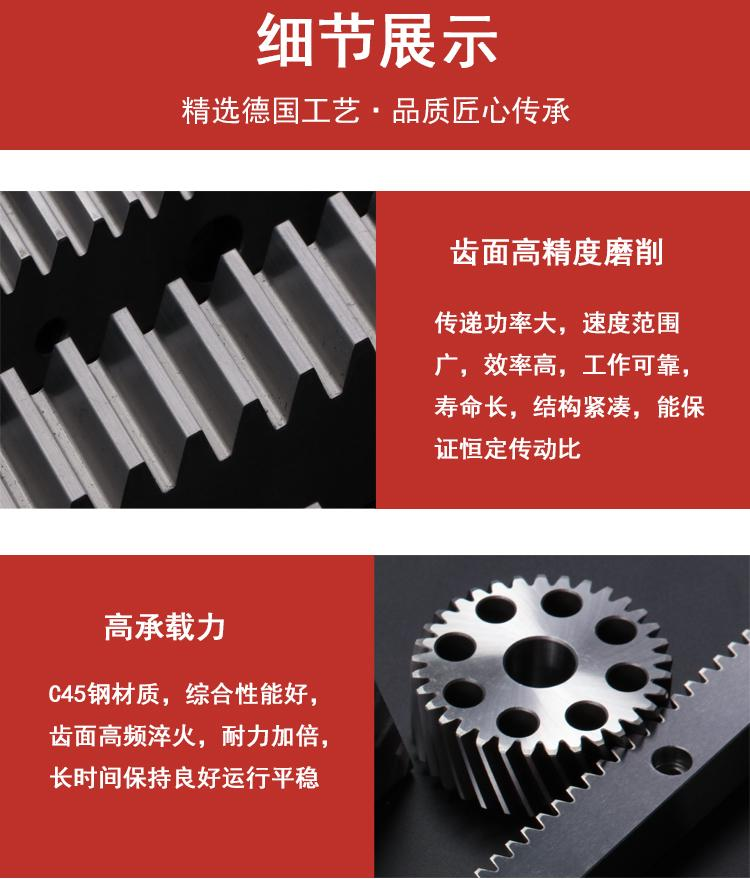

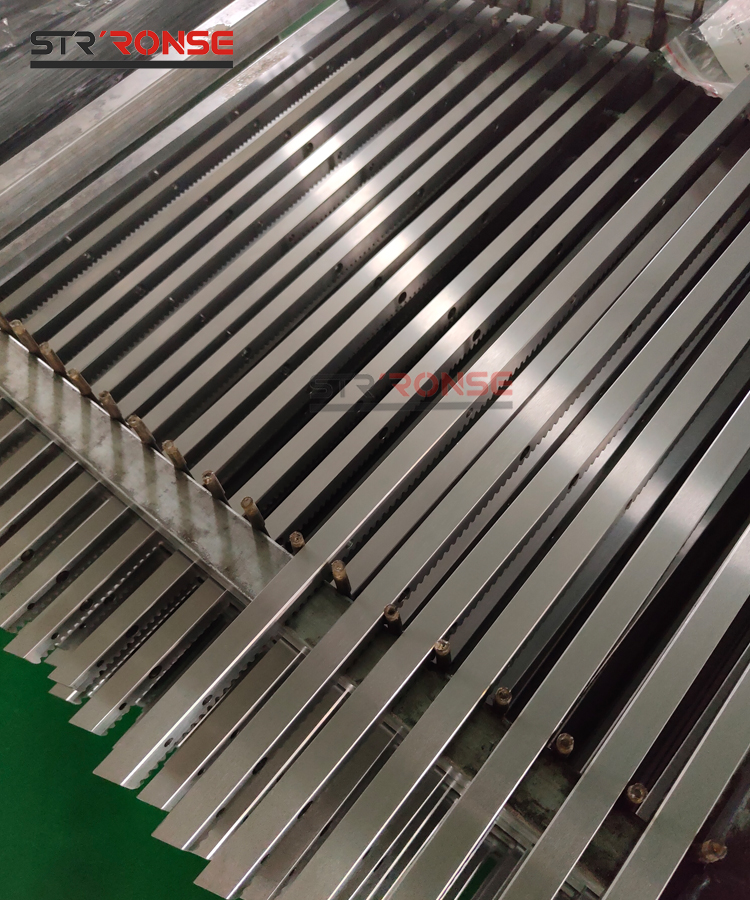

Hardened rack

Material: C45# steel;

High frequency quenching of tooth surface, hardness reaches 50-55HRC;

It is produced by a special machine imported from Germany, with high-precision grinding, and the overall pitch line error is less than or equal to 0.02mm;

German quality, quality is far better than domestic, cost-effective.

gear

Material: 20CrMnTi (gear steel)

After customizing according to customer drawings, carburizing and quenching, and finally high-precision grinding, the hardness reaches 58-63HRC German quality, excellent quality and cost-effective.

Applicable industries:

Automated robots (economical rack solution, reliable operation, long product life)

Gantry machining center (providing high-load, precision solutions)

Laser cutting machine (high acceleration, high operation, high precision)

Aluminum profiles, woodworking processing centers (provide cost-effective racks, optimize product quality)

Other fields (provide professional solutions for various linear drive equipment)

.png)

| Order no. | Module | L1 | L2 | z | b | ha | h | f+0.5 | a | l | h1 | d1 | d2 | t | a1 | l1 | d3 | kg |

| 1902.405 | 2 | 500 | 8.5 | 75 | 24 | 24 | 22 | 2 | 62.5 | 125 | 8 | 7 | 11 | 7 | 31.7 | 436.6 | 5.7 | 2.1 |

| 1902.401 | 2 | 1000 | 8.5 | 150 | 24 | 24 | 22 | 2 | 62.5 | 125 | 8 | 7 | 11 | 7 | 31.7 | 936.6 | 5.7 | 4.1 |

| 1903.405 | 3 | 500 | 10.3 | 50 | 29 | 29 | 26 | 2 | 62.5 | 125 | 9 | 10 | 15 |

9 |

35 | 430 | 7.7 | 2.9 |

| 1903.401 | 3 | 1000 | 10.3 | 100 | 29 | 29 | 26 | 2 | 62.5 | 125 | 9 | 10 | 15 | 9 | 35 | 930 |

7.7 |

5.9 |

| 1904.405 | 4 | 506.66 | 13.8 | 38 | 39 | 39 | 35 | 3 | 62.5 | 125 | 12 | 10 | 15 | 9 | 33.3 | 433 | 7.7 | 5.4 |

| 1904.401 | 4 | 1000 | 13.8 | 75 | 39 | 39 | 35 | 3 | 62.5 | 125 | 12 | 10 | 15 | 9 | 33.3 | 933.4 | 7.7 | 10.7 |

| 1905.405 | 5 | 500 | 17.4 | 30 | 49 | 39 | 34 | 3 | 62.5 | 125 | 12 | 14 | 20 | 13 | 37.5 | 425 | 11.7 | 6.5 |

| 1905.401 | 5 | 1000 | 17.4 | 60 | 49 | 39 | 34 | 3 | 62.5 | 125 | 12 | 14 | 20 | 13 | 37.5 | 925 | 11.7 | 13 |

| 1906.405 | 6 | 500 | 20.9 | 25 | 59 | 49 | 43 | 3 | 62.5 | 125 | 16 | 18 | 26 | 17 | 37.5 | 425 | 15.7 | 9.9 |

| 1906.401 | 6 | 1000 | 20.9 | 50 | 59 | 49 | 43 | 3 | 62.5 | 125 | 16 | 18 | 26 | 17 | 37.5 | 925 | 15.7 | 19.8 |

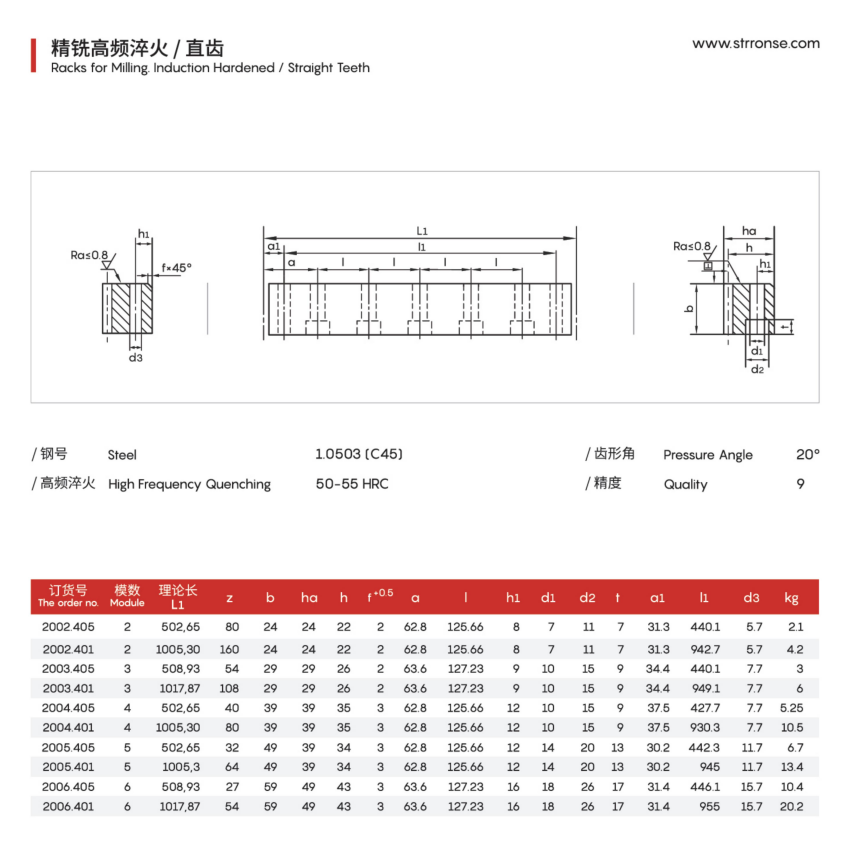

| Order no. | Module | L1 | z | b | ha | h | f+0.5 | a | l | h1 | d1 | d2 | t | a1 | l1 | d3 | kg |

| 2002.405 | 2 | 502.65 | 80 | 24 | 24 | 22 | 2 | 62.8 | 125.66 | 8 | 7 | 11 | 7 | 31.3 | 440.1 | 5.7 | 2.1 |

| 2002.401 | 2 | 1005.3 | 160 | 24 | 24 | 22 | 2 | 62.8 | 125.66 | 8 | 7 | 11 | 7 | 31.3 | 942.7 | 5.7 | 4.2 |

| 2003.405 | 3 | 508.93 | 54 | 29 | 29 | 26 | 2 | 62.6 | 125.23 | 9 | 10 | 15 |

9 |

34.4 | 440.1 | 7.7 | 3 |

| 2003.401 | 3 | 1017.87 | 108 | 29 | 29 | 26 | 2 | 62.6 | 125.23 | 9 | 10 | 15 | 9 | 34.4 | 949.0 |

7.7 |

6 |

| 2004.405 | 4 | 502.65 | 40 | 39 | 39 | 35 | 3 | 62.8 | 125.66 | 12 | 10 | 15 | 9 | 37.5 | 427.7 | 7.7 | 5.25 |

| 2004.401 | 4 | 1005.3 | 80 | 39 | 39 | 35 | 3 | 62.8 | 125.66 | 12 | 10 | 15 | 9 | 37.5 | 930.3 | 7.7 | 10.5 |

| 2005.405 | 5 | 502.65 | 32 | 49 | 39 | 34 | 3 | 62.8 | 125.66 | 12 | 14 | 20 | 13 | 30.2 | 442.3 | 11.7 | 6.7 |

| 2005.401 | 5 | 1005.3 | 64 | 49 | 39 | 34 | 3 | 62.8 | 125.66 | 12 | 14 | 20 | 13 | 30.2 | 945 | 11.7 | 13.4 |

| 2006.405 | 6 | 508.93 | 27 | 59 | 49 | 43 | 3 | 62.6 | 125.23 | 16 | 18 | 26 | 17 | 31.4 | 446.1 | 15.7 | 10.4 |

| 2006.401 | 6 | 1017.87 | 54 | 59 | 49 | 43 | 3 | 62.6 | 125.23 | 16 | 18 | 26 | 17 | 31.4 | 955 | 15.7 | 20.2 |