The planetary gearbox for AGVs. Compact and highliy resilient.

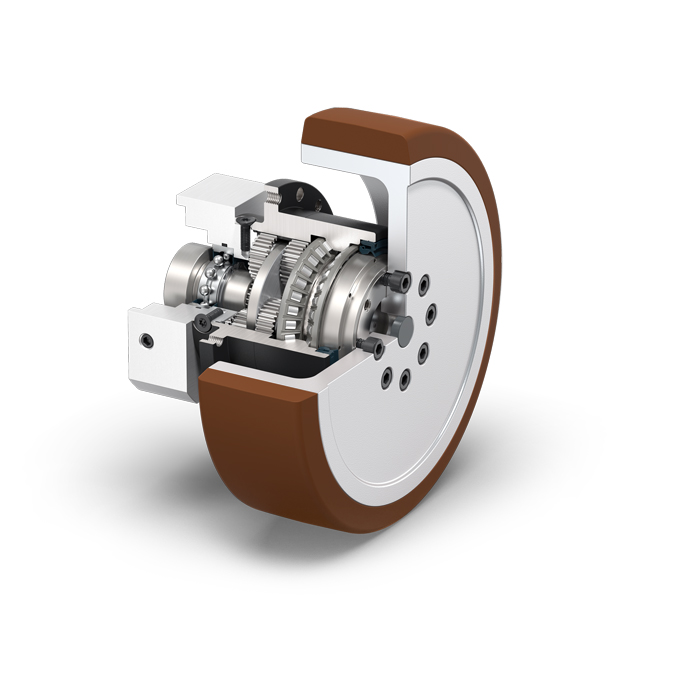

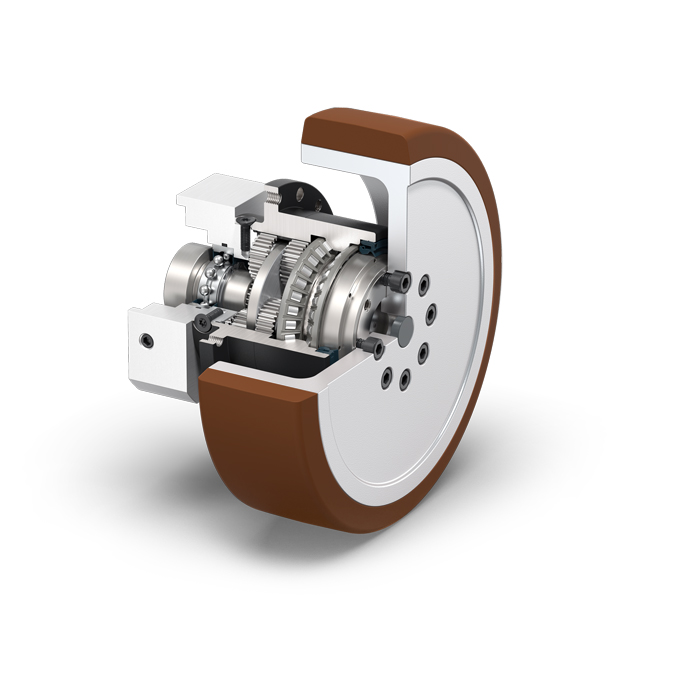

Every detail counts, so that a gearbox can fulfill application-specific requirements in an optimum way.

Using the installation interface, the reducer can be directly installed on the vehicle without additional adapters. The reduction gear is almost surrounded by the gear wheels, so the installation space required inside the vehicle is reduced. The pre-tensioned two angular contact roller bearings of this reducer can withstand high radial forces. Reliable operation and permanent lubrication.

AGVs are called automated guided vehicles. They are an efficient, reliable and versatile material handling solution. NEUGART planetary gearbox meets the requirements of AGV manufacturers, with high power density but small size, and various types of speed ratios to choose from. An AGV is a mobile robot that uses markers, wires, magnets, lasers, or other instruments for navigation. AGVs are commonly used in industrial applications to transport materials in factories, warehouses and even airports. Whatever your requirements for your AGV drive: we can provide the ideal gearbox solution for your vehicle.

Planetary gearbox for industrial drop ground trucks. Compact and high load-carrying capacity. AGVs have special requirements in terms of drive technology. These include high radial loads, space saving design, 24/7 availability and energy efficiency. With its special output bearing concept and the option of mounting directly to the vehicle chassis, our NGV planetary gearboxes precisely meet these requirements.

In order to make the gear unit as suitable as possible for the specific application, every detail cannot be ignored. AGVs are built to transport high loads for long periods of time. It has high demands on details, design and mechanical parts. But our NGV high precision gearbox can meet these requirements. This gearbox is compact, efficient and extremely durable. We specifically optimize it to make it more suitable for AGV.

This NGV planetary gearbox uses a direct installation interface, which can directly install the gearbox on the vehicle without additional adapters. The outside of the gearbox is almost surrounded by the wheel, so the installation space required in the vehicle interior of this gearbox is minimized. The pre-tightening angular contact roller bearing inside the gearbox allows the gearbox to have a strong radial load capacity. It can be matched with different motors, and different types of motors can be installed together with this NGV gearbox. It has been proved by practice that all gearboxs in the NEUGART series have high efficiency, are maintenance-free, and are still safe and reliable under continuous operation.

NGV reducer size drawing download:

| Gearbox characteristics | NGV064 | NGV090 | NGV110 | |

| Reduer | 9;12;15;16;20;25;32;40;64 | |||

| Service life |

h |

30.000 | ||

| Efficiency at full load | % | ≥95 | ||

| Min operating temperature/max operating temperature | ℃ | -25/90 | ||

| Protection class |

IP65(at the output side) |

|||

| Standard lubrication | Grease (lifetime lubrication) | |||

| Food grade lubrication | Grease (lifetime lubrication) | |||

| Low temperature lubrication | Grease (lifetime lubrication) | |||

| Installation position | 任意 | |||

| Standard backlash | arcmin |

≤12 |

≤9 | ≤9 |

| Torsional stiffness | Nm/arcmin | 7.3-11.5 | 19.5-38.5 | 52-95 |

| Gearbox weight | kg | 1.6-1.7 | 4.0 | 8.5-8.7 |

| Standard surface | Housing: Steel - heat-treated and post-oxidized(black) | |||

| Running noise | dB/(A) | 60 | 62 | 65 |

| Max bending moment based on the gearbox input flange | Nm | 8 | 16 | 40 |

Nominal output torque

| NGV064 | NGV090 | NGV110 | I |

| 44 | 130 | 210 | 9 |

| 44 | 120 | 260 | 12 |

| 44 | 110 | 230 | 15 |

| 44 | 120 | 260 | 16 |

| 44 | 120 | 260 | 20 |

| 40 | 110 | 230 | 25 |

| 44 | 120 | 260 | 32 |

| 40 | 110 | 230 | 40 |

| 18 | 50 | 120 | 64 |

| Output shaft loads | NGV064 | NGV090 | NGV110 | |

| Radial force for 20000h/30000h |

N |

2000-2300 | 3650-4100 | 4550-5150 |

| Axial force for 20000h/30000h | 2500-2850 | 4800-5450 | 5600-6450 | |

| Tilting moment for 20000h | Nm | 96-110 | 248-278 |

360-407 |