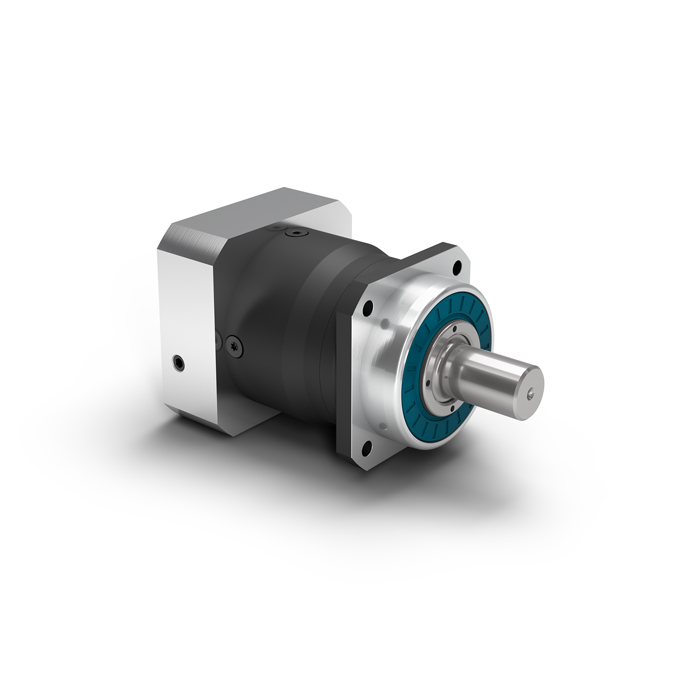

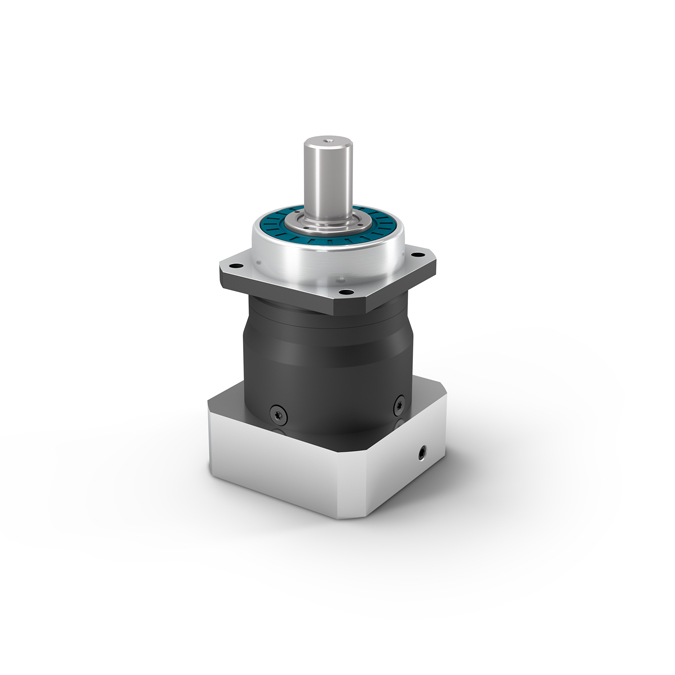

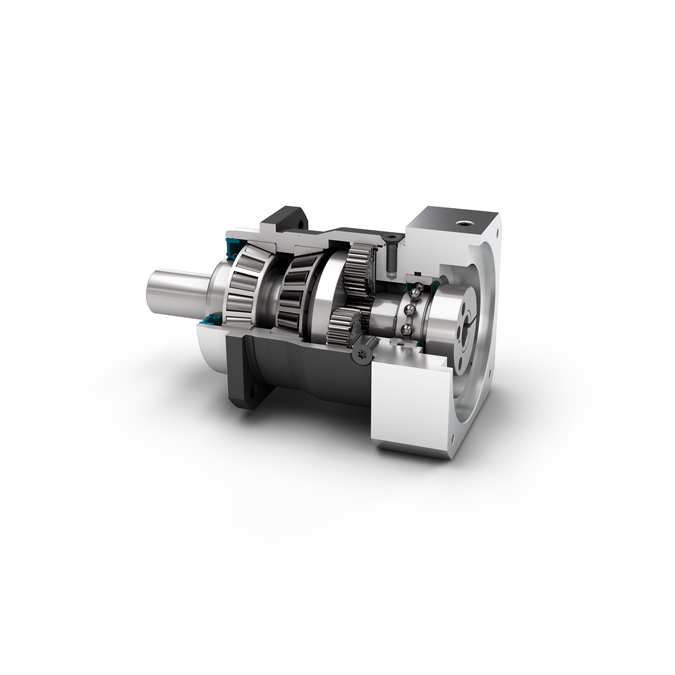

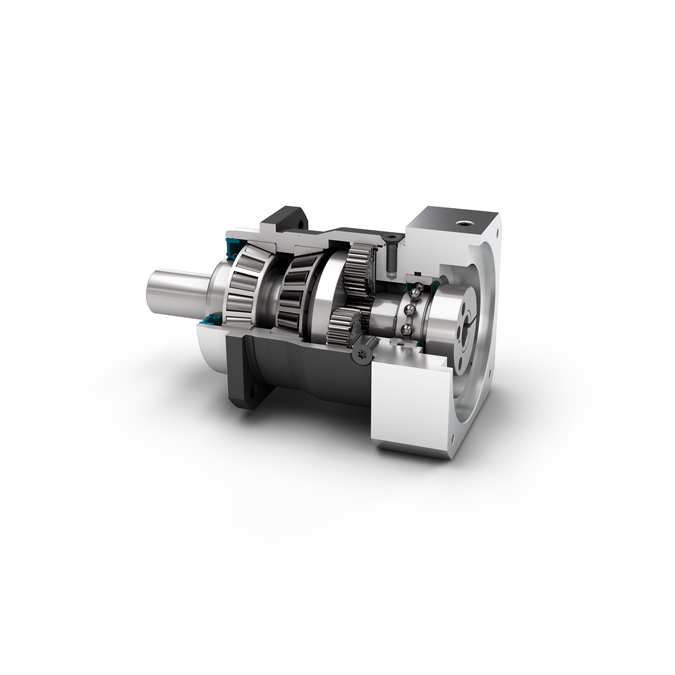

This is progress: In this planetary gearbox, precision and cost effectiveness meet.

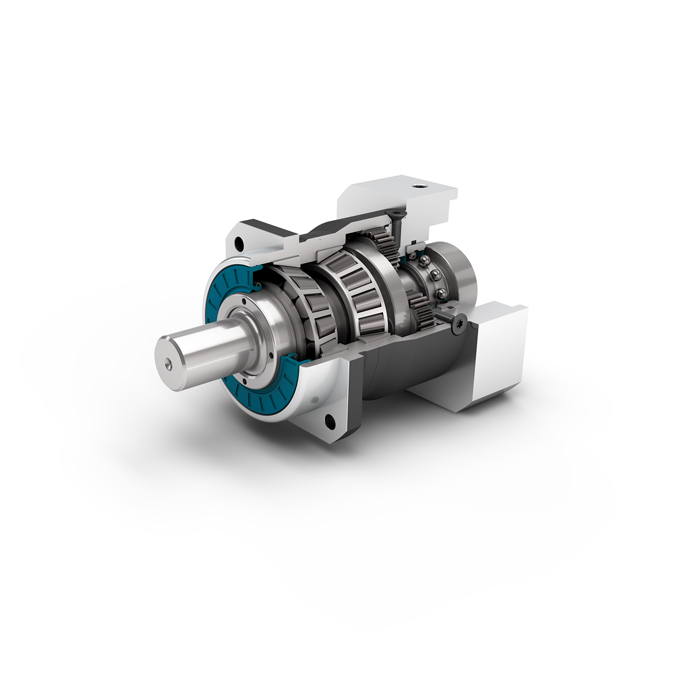

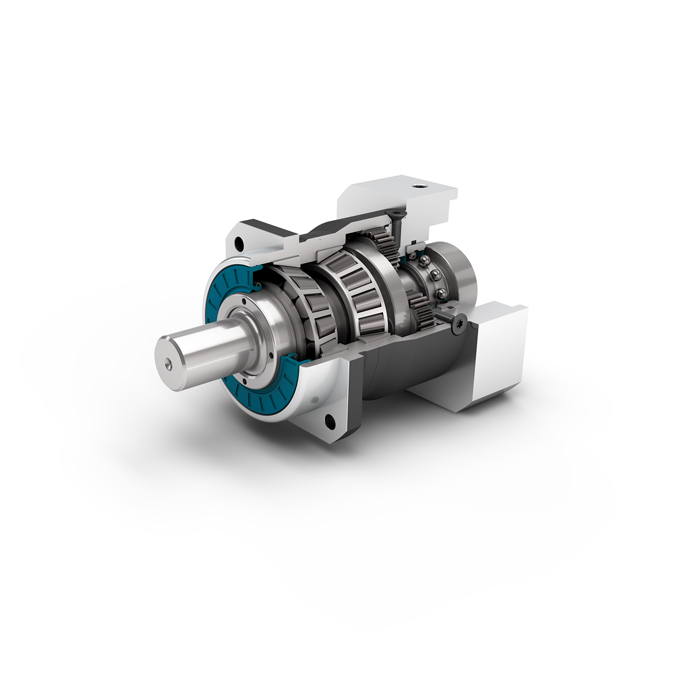

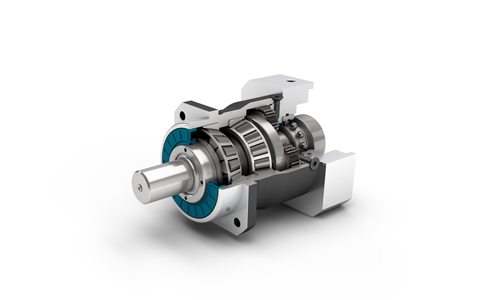

The PLHE is the world’s first combination of economy and precision planetary gearboxes. The prestressed tapered roller bearings of our planetary gearboxes safeguard great stiffness even under the highest loads. The seal we have developed provides the perfect protection against dust and water jets.

PLHE planetary gearbox has been greatly improved in accuracy and economy through the optimization of economical gearbox, and it is also the first gearbox that integrates economical and high-precision. Self-developed seals can effectively prevent splash water and dust from entering the machine, and can be protected with the help of intelligent structure.

This gearbox can also play the characteristics of this gearbox in a more demanding environment. The preloaded tapered roller bearing ensures that the gearbox has this high rigidity. Even if the running direction is frequently switched, the output bearing can maintain with zero backlash. Good characteristics are maintained even under continuous load.

Product description

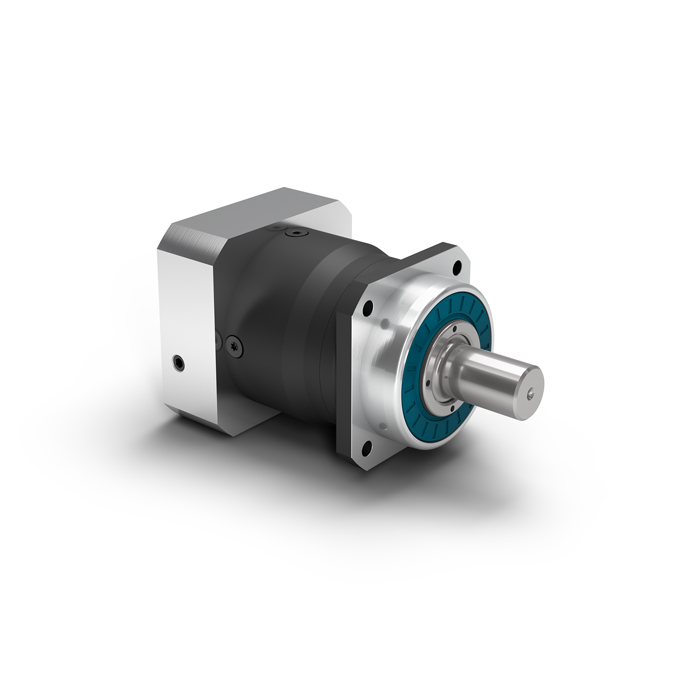

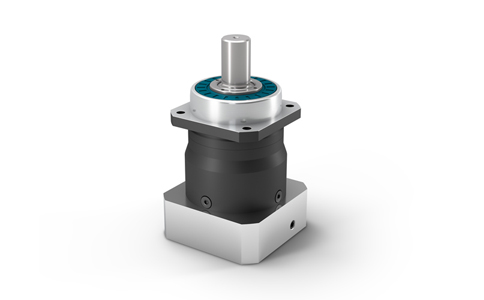

NEUGART's planetary gear units with output shaft are suitable for a wide variety of drive solutions.

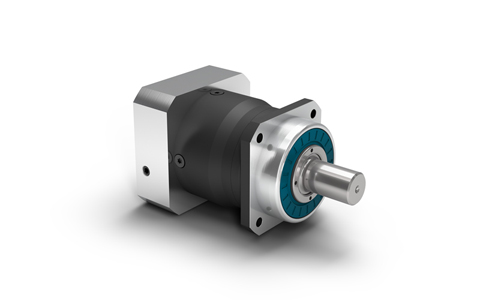

The output shaft can be selected in different forms, for example, as a transmission shaft with feather keys to reliably transmit power in a mutually meshing manner.

The Feather Key is a universal connecting element found in numerous drive assemblies, creating a fast and reliable connection between planetary gearboxes with output shafts and your application

Planetary gearboxes with smooth output shafts are ideal for friction-fit connection to the coupling. So you also get excellent torque transfer when running in reverse.

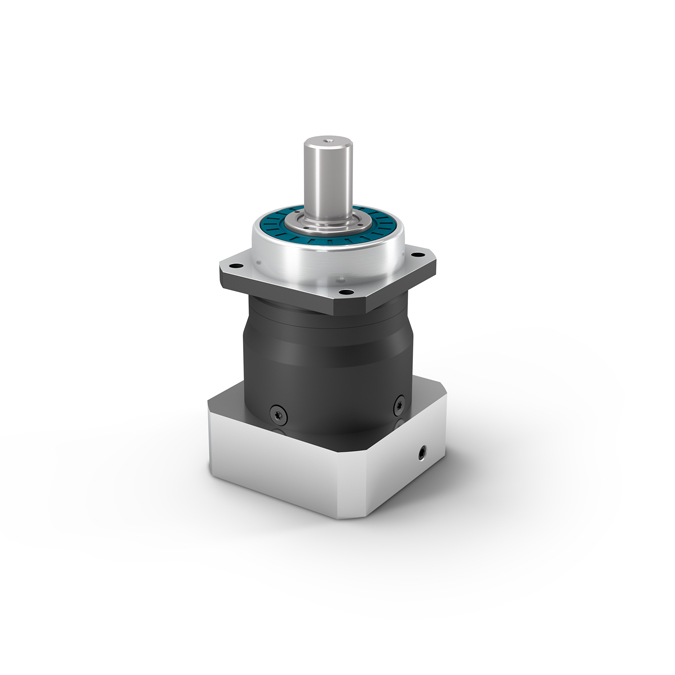

The planetary gearbox with output shaft can also be connected to your drive system via a multi-tooth shaft. With this meshing output shaft according to DIN 5480, you can install other drive components, such as pinions, very simply by intermeshing with the internal teeth.

The drive flange of the planetary gearbox can be individually adapted to the motor. The compact unit of planetary gear unit with output shaft and servo motor increases flexibility.

Due to the low moment of inertia of the output shaft, planetary gearboxes with output shafts are the ideal solution for many dynamic applications.

Due to the wide variety of planetary gearboxes with output shafts, we offer you maximum freedom in choosing the right product for your specific application.

PLHE has an extra-long centering ring, which can be installed in any position, the input flange can be adapted to special motors; the output shaft has a variety of styles, and the gearbox with pinion can be customized; optimized moment of inertia locking The system adopts high-precision gears, which can maintain a high meshing accuracy. The torsional stiffness of the gearbox is between 2.6-27.5Nm, and the weight can be selected from 1.5-8.8kg. The specific gearbox data selection sample will have complete data, and it can also be displayed through NCP when adapting the motor.

Product advantages

High precision, economical, high rigidity, high load, completely sealed

Optional

Various types of output shafts

lubricating

Optimized tensioning system

Various types of drive flanges

installed pinion

Use

Packaging equipment, printing industry, agricultural product industry

Features

Rigidity under high loads

high sealing

Can be installed anywhere

Lifetime lubrication maintenance free

precise meshing

PLHE gearbox model speed ratio

PLHE060-3、PLHE060-4、PLHE060-5、PLHE060-7、PLHE060-8、PLHE060-10、PLHE060-9、PLHE060-12、PLHE060-15、PLHE060-16、PLHE060-20、PLHE060-25、PLHE060-32、PLHE060-40、PLHE060-64、PLHE060-100

PLHE080-3、PLHE080-4、PLHE080-5、PLHE080-7、PLHE080-8、PLHE080-10、PLHE080-9、PLHE080-12、PLHE080-15、PLHE080-16、PLHE080-20、PLHE080-25、PLHE080-32、PLHE080-40、PLHE080-64、PLHE080-100

PLHE120-3、PLHE120-4、PLHE120-5、PLHE120-7、PLHE120-8、PLHE120-10、PLHE120-9、PLHE120-12、PLHE120-15、PLHE120-16、PLHE120-20、PLHE120-25、PLHE120-32、PLHE120-40、PLHE120-64、PLHE120-100

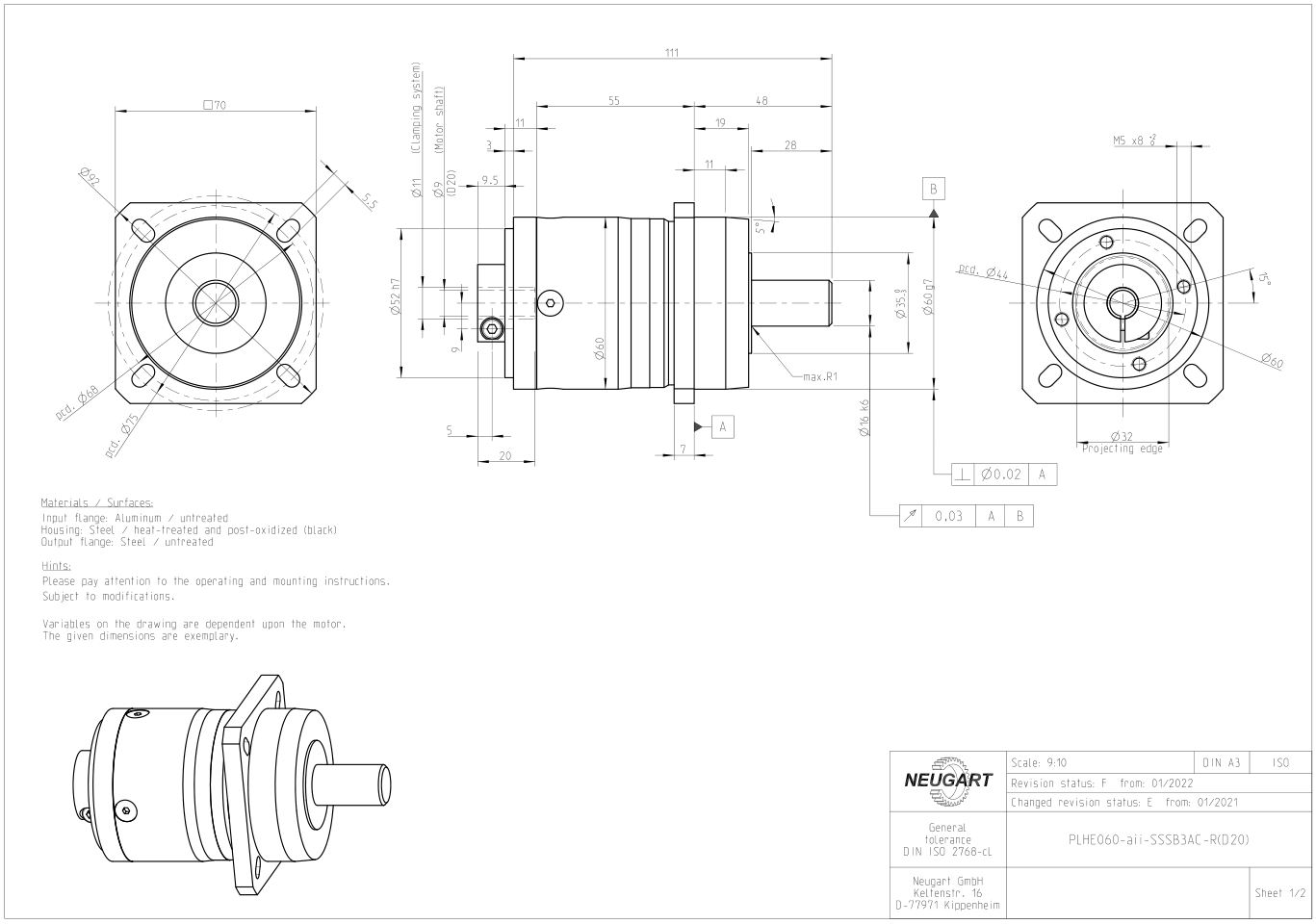

PLHE60 gearbox dimension drawing

PLHE planetary gearbox drawing download:

PLHE selection reference diagram

| Gearbox characteristics | PLHE060 | PLHE080 | PLHE120 | P | |

| Reduer | 3, 4, 5, 7, 8, 10 | 1 | |||

| Reduer | 9, 12, 15, 16, 20, 25, 32, 40,64,100 | 2 | |||

| Service life | h | 30.000 | |||

| Efficiency at full load | % | 97/96 | |||

| Min operating temperature/max operating temperature | ℃ | -25/90 | |||

| Protection class |

IP65 |

||||

| Standard lubrication | Grease (lifetime lubrication) | ||||

| Food grade lubrication | Grease (lifetime lubrication) | ||||

| Low temperature lubrication | Grease (lifetime lubrication) | ||||

| Lnstallation location | Any | ||||

| Standard return clearance | arcmin | <10-<12 | <7-<9 | <7-<9 | |

| Torsional stiffness | Nm/arcmin | 2.6-4.6 | 7.3-12.3 | 16.7-27.5 | |

| Reducer weight | kg | 1.5-1.8 | 3.0-4.0 | 6.8-8.8 | |

| Standard case surface | Housing: Steel - heat-treated and post-oxidized(black) | ||||

| Running noise | dB/(A) | 58 | 60 | 65 | |

| Max bending moment based on the gearbox input flange | Nm | 8 | 16 | 40 | |

Nominal Output torque

| PLHE060 | PLHE080 | PLHE120 | I | P |

| 28 | 85 | 115 | 3 | 1 |

| 38 | 115 | 155 | 4 | |

| 40 | 110 | 195 | 5 | |

| 25 | 65 | 135 | 7 | |

| 18 | 50 | 120 | 8 | |

| 15 | 38 | 95 | 10 | |

| 44 | 130 | 210 | 9 | 2 |

| 44 | 120 | 260 | 12 | |

| 44 | 110 | 230 | 15 | |

| 44 | 120 | 260 | 16 | |

| 44 | 120 | 260 | 20 | |

| 40 | 110 | 230 | 25 | |

| 44 | 120 | 260 | 32 | |

| 40 | 110 | 230 | 40 | |

| 18 | 50 | 120 | 64 | |

| 15 | 38 | 95 | 100 |

Output shaft loads

| PLHE060 | PLHE080 | PLHE120 | ||

| Radial force for 20000 h | N | 3200 | 5500 | 6000 |

| Axial force for 20000 h | N | 4400 | 6400 | 8000 |

| Radial force for 30000 h | N | 3200 | 4800 | 5400 |

| Axial force for 30000 h | N | 3900 | 5700 | 7000 |

| Tilting moment for 20000 h | Nm | 191 | 383 | 488 |

| Tilting moment for 30000 h | Nm | 191 | 335 | 439 |

geometry

| PLHE060 | PLHE080 | PLHE120 | P | ||

| Shaft diameter output | mm | 16 | 22 | 32 | |

| Centering diameter output | mm | 60 | 70 | 90 | |

| Housing diameter | mm | 60 | 80 | 115 | |

| Flange cross section output | mm | 70 | 80 | 110 | |

| Min. total lenght | mm | 127 | 159 | 199.5 | 1 |

| 139.5 | 177 | 227 | 2 | ||

| Shaft lenght output | mm | 48 | 56 | 88 |