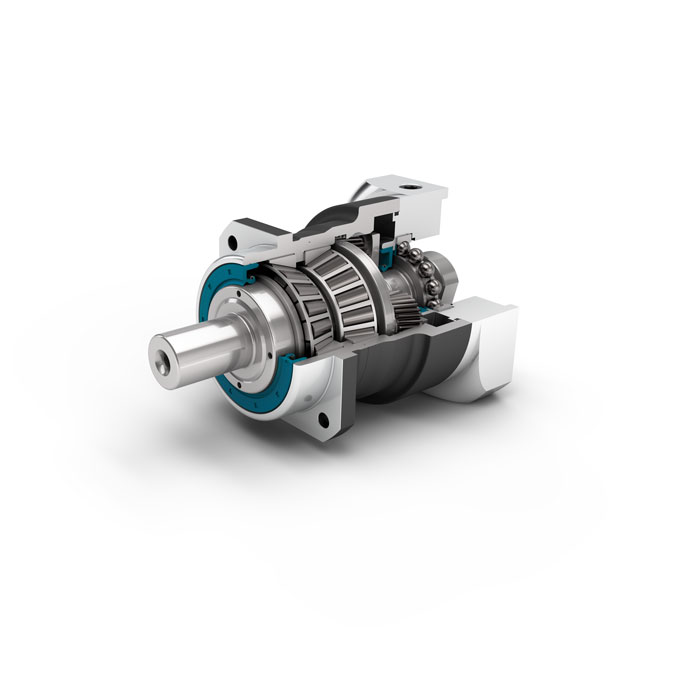

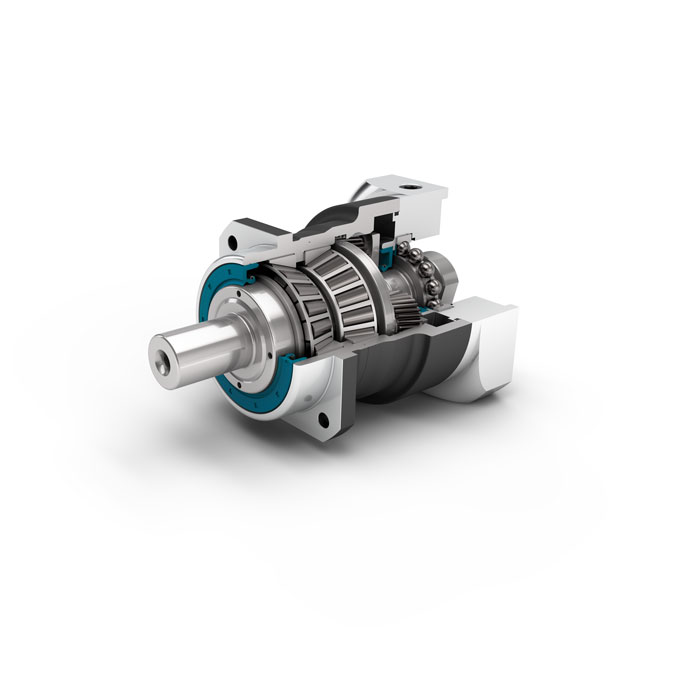

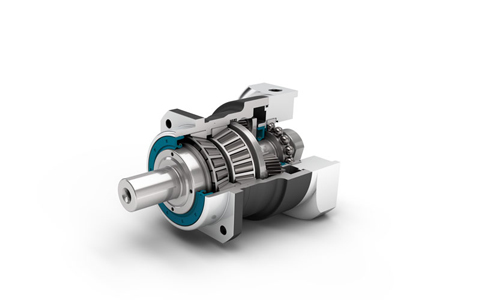

The helical-toothed precision planetary gearbox for low-noise operation and high bearing loads.

Our PSN embodies pure progress: Its innovative helical teeth safeguard low-noise operations. This precision planetary gearbox minimizes vibrations, and therefore increases the quality of your workpiece surfaces even under the highest bearing loads.

PSN planetary gearbox is a high-precision helical gear gearbox of NEUGART brand, which can realize synchronous operation with low noise, and the bearing has a strong load capacity.

The improvement of the PSN compared to other precision models is that the new gear of this gearbox can achieve low noise operation during operation. When using this gearbox, the vibration of the gearbox is greatly reduced - which can improve the surface quality of the workpiece when the bearing load is high.

product description

PSN planetary gearboxes are equipped with preloaded tapered roller bearings suitable for operation in extreme conditions. Even if the direction of operation is frequently switched, this gear unit does not lose the necessary rigidity and is therefore also suitable for high loads. Because of the high-precision helical gears used by PSN, the machine does not need to take other noise reduction measures during operation, and the gearbox itself can operate with low noise.

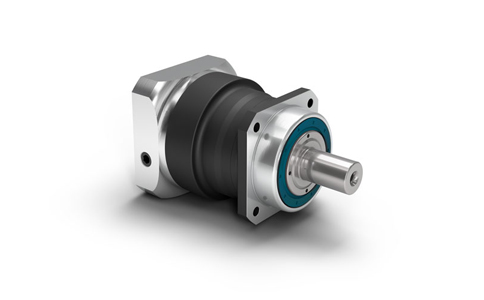

The return clearance of the PSN gearbox is small, at 1-5arcmin, or even less than 1 arcmin. It has high precision and can be installed in any position. The input flange of this gearbox can be adapted to special motors, and can also be lubricated for life. Maintenance-free, reducing the time cost of work, diversified output shafts, splines with keys, etc. can be selected or other customized services, and an optimized moment of inertia system. The rated torque of the PSN gearbox is 28-950Nm, the radial force is 3200-20000N, and the axial force is 4400-19000N. This precision coaxial gearbox adopts square output flange and radial shaft seal, which is easy to install and has good sealing performance, which can effectively prevent dust from entering the machine during operation. Equipped with preloaded tapered roller bearings, the output end of the gearbox has a long centering ring, so the gearbox has high precision while running stably, and the operation process is also low noise. Now there is a gear gearbox, and the high-precision gears are pre-installed on the gearbox, which effectively saves the time for gear installation and makes the work more convenient and fast.

The service life of the PSN gearbox is 30,000h, and it can operate at a temperature between -25-90°C. It has three lubrication methods: food, low temperature, and standard. The weight of the gearbox ranges from 1.9-41.7kg, depending on the technical selection. The model determines the data.

Product advantages

Excellent rigidity under high loads

Inclined gears bring quality improvement

runs very quietly

completely sealed

Can be installed anywhere

Lubricated for life and therefore maintenance-free

Optional

Return clearance: standard return clearance, reduced return clearance

Various types of output shafts: with flat key output shaft, smooth output shaft, spline output shaft

Lubrication: Standard Lubrication, Food Grade Lubrication, Low Temperature Lubrication

Optimized tensioning system

installed pinion

Features

Machine tools, printing industry, lithium battery, truss

High precision, low noise, low backlash, low noise

PSN helical planetary gearbox drawing download:

PSN070 Reference Drawing

PSN090 Reference Drawing

PSN0115 Reference Drawing

PSN0142 Reference Drawing

PSN0190 Reference Drawing

| Gearbox characteristics | PSN070 | PSN090 | PSN115 | PSN142 | PSN190 | P | |

| Reduer | 3, 4, 5, 7,8,10 | 1 | |||||

| Reduer | 12,15,16,20,25,35,40,50,70,100 | 2 | |||||

| Service life |

h |

20.000 | |||||

| Service life at T2N×0.88 | h | 30.000 | |||||

| Efficiency at full load | % | 98/97 | |||||

| Min operating temperature/max operating temperature | ℃ | -25/90 | |||||

| Protection class |

IP65 |

||||||

| Standard lubrication | Grease (lifetime lubrication) | ||||||

| Food grade lubrication | Grease (lifetime lubrication) | ||||||

| Low temperature lubrication | Grease (lifetime lubrication) | ||||||

| Installation position | Any | ||||||

| Standard backlash | arcmin | <3-<5 | |||||

| Reduced backlash | arcmin | <2 | <1 | <1 | <1 | <1 | |

| Torsional stiffness | Nm/arcmin | 3.6-5.0 | 9.2-13.8 | 22.0-39.5 | 61.0-85.0 |

179.0-255.0 |

|

| Gearbox weight | kg | 1.9-2.7 | 3.4-4.1 | 6.8-8.2 | 15.3-17.6 | 34.9-41.7 | |

| Standard surface | Housing: Steel - heat-treated and post-oxidized(black) | ||||||

| Running noise | dB/(A) | 57 | 58 | 63 | 66 | 68 | |

| Max bending moment based on the gearbox input flange | Nm | 18 | 18/38 | 38/80 | 80/180 | 180/300 | |

Nominal Output torque

| PSN070 | PSN090 | PSN115 | PSN142 | PSN190 | I | P |

| 29 | 54 | 135 | 380 | 845 | 3 |

1 |

| 39 | 80 | 180 | 470 | 950 | 4 | |

| 40 | 80 | 175 | 405 | 950 | 5 | |

| 37 | 78 | 175 | 355 | 900 | 7 | |

|

39 |

75 | 155 |

350 |

- | 8 | |

| 28 | 59 | 140 | 305 | 750 | 10 | |

| 29 | 54 | 135 | 380 | 845 | 12 |

2 |

| 29 | 54 | 135 | 380 | 845 | 15 | |

| 39 | 80 | 180 | 450 | 950 | 16 | |

| 39 | 80 | 180 | 450 | 950 | 20 | |

| 40 | 80 |

175 |

405 | 950 | 25 | |

| 40 | 80 | 175 | 405 | 950 | 35 | |

| 39 | 80 | 180 | 470 | 950 | 40 | |

| 40 | 80 | 175 | 405 | 950 | 50 | |

| 37 | 78 | 175 | 355 | 900 | 70 | |

| 28 | 59 | 140 | 305 | 750 | 100 |

Output shaft loads

| PSN070 | PSN090 | PSN115 | PSN142 | PSN190 | |

| Radial force for 20000 h | 3200 | 5500 | 6000 | 13000 | 20000 |

| Axial force for 20000 h | 4400 | 6400 | 8000 | 15000 | 19000 |

| Radial force for 30000 h | 3200 | 4800 | 5400 | 11500 | 17500 |

| Axial force for 30000 h | 3900 | 5700 | 7000 | 13500 | 18500 |

| Tilting moment for 20000 h | 203 | 419 | 562 | 1566 | 2887 |

| Tilting moment for 30000 h | 203 | 366 | 506 | 1385 | 2526 |

|

|

PSN070 | PSN090 | PSN115 | PSN142 | PSN190 | P |

| Shaft diameter output | 16 | 22 | 32 | 40 | 55 | |

| Centering diameter output | 60 | 70 | 90 | 130 | 160 | |

| Flange cross section output | 70 | 80 | 110 | 142 | 190 | |

| Min. total lenght | 134 | 157 | 202.5 | 261.5 | 310.5 | 1 |

| 162.5 | 179 | 224.5 | 292.5 | 355.5 | 2 | |

| Shaft lenght output | 48 | 56 | 88 | 110 | 112 |