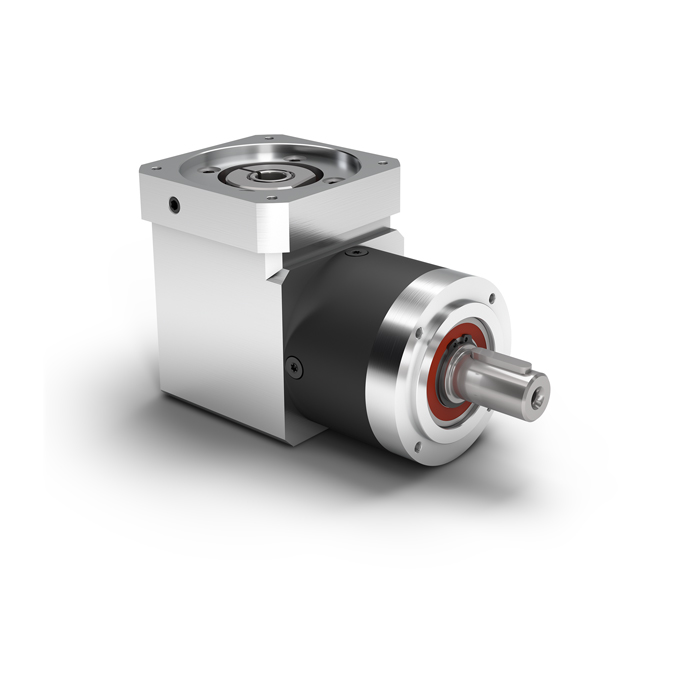

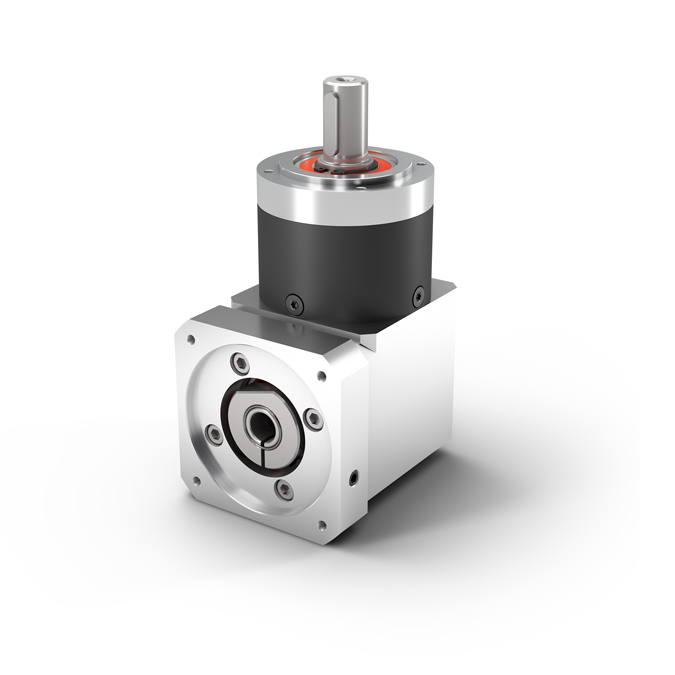

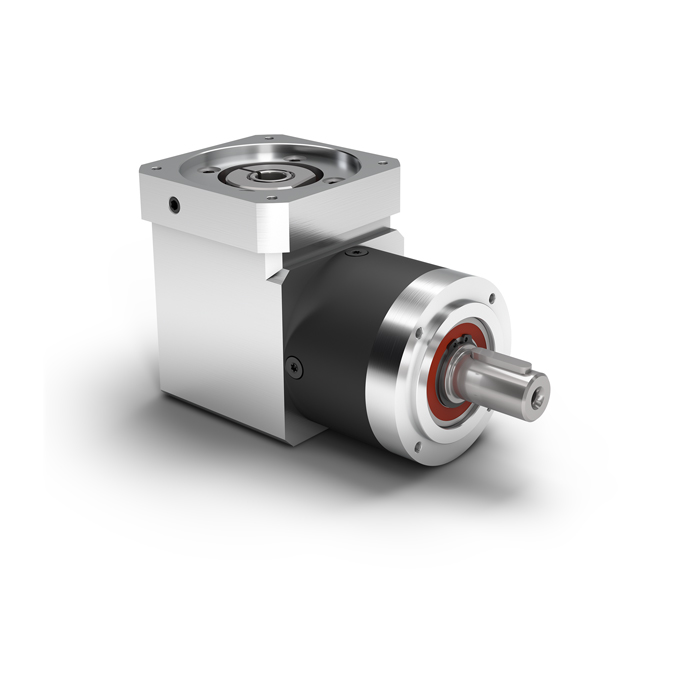

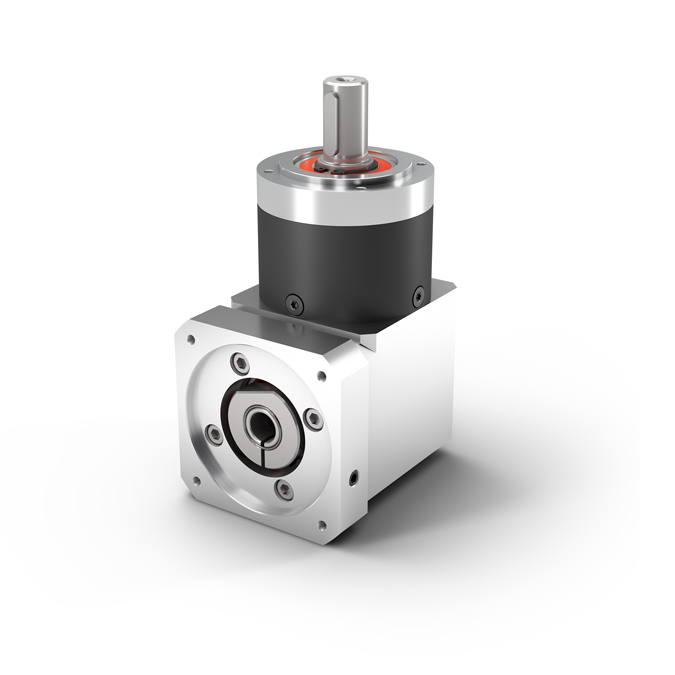

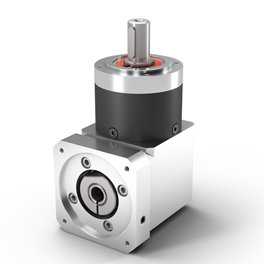

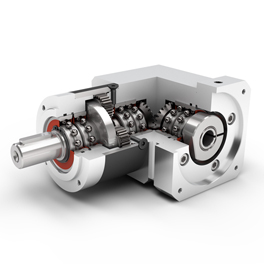

The versatile right angle planetary gearbox with lower weight and appealing cost effectiveness.

The WPLE is a consistent continuation of the benefits offered by the Economy Line. With its compact, but powerful design, it is ideal for dynamic multiple axis systems. Our right angle gearbox features lifetime lubrication, is easy to install, all this at an unrivalled price-performance ratio.

WPLE planetary gearbox is an economical right-angle gearbox in the NEUGART series. This gearbox continuously enlarges the advantages of an economical gearbox, and with its compact and powerful structure, it is an ideal choice for dynamic multi-axis systems. This gearbox is lubricated for life and maintenance-free, easy to operate during installation, and cost-effective.

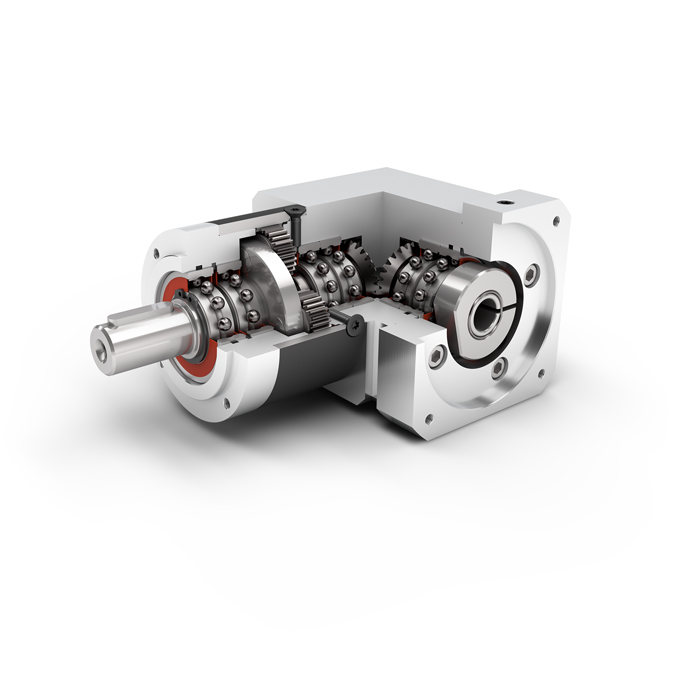

Product description

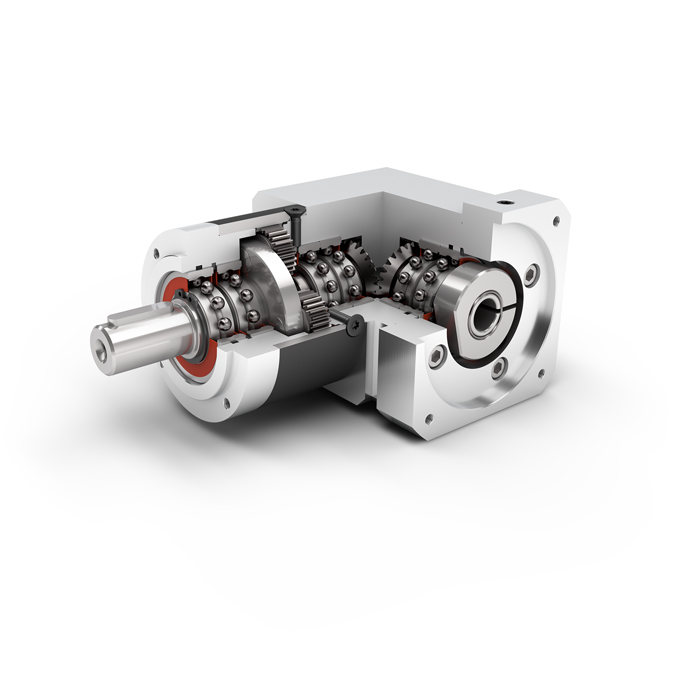

The input flange of the WPLE planetary gearbox can be adapted to a special motor, the rotation is in the same direction, the output shaft style is diversified, the transmission range is wide, and the speed ratio is from i=3 to i=512. Compared with other similar products, WPLE reduces its dead weight by 25% because of its high torque. As a product in the right-angle planetary gearbox series, the WPLE multi-functional product is particularly prominent, so it has a high cost performance. The use of this maintenance-free right-angle planetary gearbox can make full use of the limited space, so the installation is flexible and suitable for a wide range of applications.

WPLE has a service life of up to 20,000 hours, is suitable for operating temperatures between -25-90°C, has three types of lubrication: low temperature, food, and standard, any safe position, and has a torsional stiffness of 22N. The weight range of the gearbox is 0.6- Choose between 13.4kg, the specific weight or other parameters can be changed according to different models. The maximum radial force of this gearbox is 2000N and the maximum axial force is 3800N.

WPLE is widely used in various industries. In lithium battery, machine tool, food, printing and other industries, NEUGART gearbox has various models and choices, and professional technology provides systematic selection solutions.

Product advantages

lightweight

compact

Simple and easy to install

Cost-effective

optional

Various types of output shafts

lubricating

Various types of drive flanges

Flexible connection of motors

Use

Food industry, pharmaceutical technology and pharmaceutical industry, agricultural product industry

Features

Extremely high dynamics in multi-axis systems

Unbeatable price/performance ratio

Great flexibility in installation

Lubricated for life and therefore maintenance-free

precise meshing

| Gearbox characteristics | WPLE040 | WPLE060 | WPLE080 | WPLE120 | P | |

| Reduer | 3, 4, 5, 7, 8, 10 | 1 | ||||

| Reduer | 9,12,15,16,20,25,32,40,64 | 2 | ||||

| Reduer | 60,80,100,120,160,200,256,320,512 | 3 | ||||

| Service life | h | 20.000 | ||||

| Efficiency at full load | % | 95/94/88 | ||||

| Min operating temperature/max operating temperature | ℃ | -25/90 | ||||

| Protection class |

IP54 |

|||||

| Standard lubrication | Grease (lifetime lubrication) | |||||

| Food grade lubrication | Grease (lifetime lubrication) | |||||

| Low temperature lubrication | Grease (lifetime lubrication) | |||||

| Installation position | Any | |||||

| Standard backlash | arcmin | <21-<28 | <16-<21 | <13-<17 | <11-<5 | |

| Torsional stiffness | Nm/arcmin | 0.5-1.0 | 1.5-2.8 | 4.0-10.4 |

9.9-22.0 |

|

| Gearbox weight | kg | 0.6-0.8 | 1.6-2.0 | 3.7-4.7 | 9.6-13.4 | |

| Standard surface | Housing: Steel - heat-treated and post-oxidized(black) | |||||

| Running noise | dB/(A) | 68 | 70 | 73 | 75 | |

| Max bending moment based on the gearbox input flange | Nm | 2 | 5 | 10.5 | 26 | |

Nominal Output torque

| WPLE040 | WPLE060 | WPLE080 | WPLE120 | I | P |

| 4.5 | 14 | 40 | 80 | 3 |

1 |

| 6 | 19 | 53 | 105 | 4 | |

| 7.5 | 24 | 67 | 130 | 5 | |

| 8.5 | 25 | 65 | 135 | 7 | |

| 6 | 18 | 50 | 120 | 8 | |

| 5 | 15 | 38 | 95 | 10 | |

| 16.5 | 44 | 130 | 210 | 9 |

2 |

| 20 | 44 | 120 | 260 | 12 | |

| 18 | 44 | 110 | 230 | 15 | |

| 20 | 44 | 120 | 260 | 16 | |

| 20 | 44 | 120 | 260 | 20 | |

| 18 | 40 | 110 | 230 | 25 | |

| 20 | 44 | 120 | 260 | 32 | |

| 18 | 40 | 110 | 230 | 40 | |

| 7.5 | 18 | 50 | 120 | 64 | |

| 20 | 44 | 110 | 260 | 60 |

3 |

| 20 | 44 | 120 | 260 | 80 | |

| 20 | 44 | 120 | 260 | 100 | |

| 18 | 44 | 110 | 230 | 120 | |

| 20 | 44 | 120 | 260 | 160 | |

| 18 | 40 | 110 | 230 | 200 | |

| 20 | 44 | 120 | 260 | 256 | |

| 18 | 40 | 110 | 230 | 320 | |

|

7.5 |

18 | 50 | 120 |

512 |

Output shaft loads

| WPLE040 | WPLE060 | WPLE080 | WPLE120 | ||

| Radial force for 20000 h | N | 200 | 400 | 750 | 1750 |

| Axial force for 20000 h | N | 200 | 500 | 1000 | 2500 |

| Radial force for 30000 h | N | 160 | 340 | 650 | 1500 |

| Axial force for 30000 h | N | 160 | 450 | 900 | 2100 |

| Tilting moment for 20000 h | Nm | 5 | 14 | 31 | 101 |

| Tilting moment for 30000 h | Nm | 4 | 12 | 27 | 86 |

Geometry

| WPLE040 | WPLE060 | WPLE080 | WPLE120 | P | ||

| Shaft diameter output | mm | 10 | 14 | 20 | 25 | |

| Centering diameter output | mm | 26 | 40 | 60 | 80 | |

| Housing diameter | mm | 40 | 60 | 80 | 115 | |

| Min. total lenght | mm | 110 | 147 | 184 | 249.5 | 1 |

| mm | 123 | 159.5 | 201.5 | 277 | 2 | |

| mm | 135.5 | 172 | 219 | 304.5 | 3 | |

| Shaft lenght output | mm | 26 | 35 | 40 | 55 |