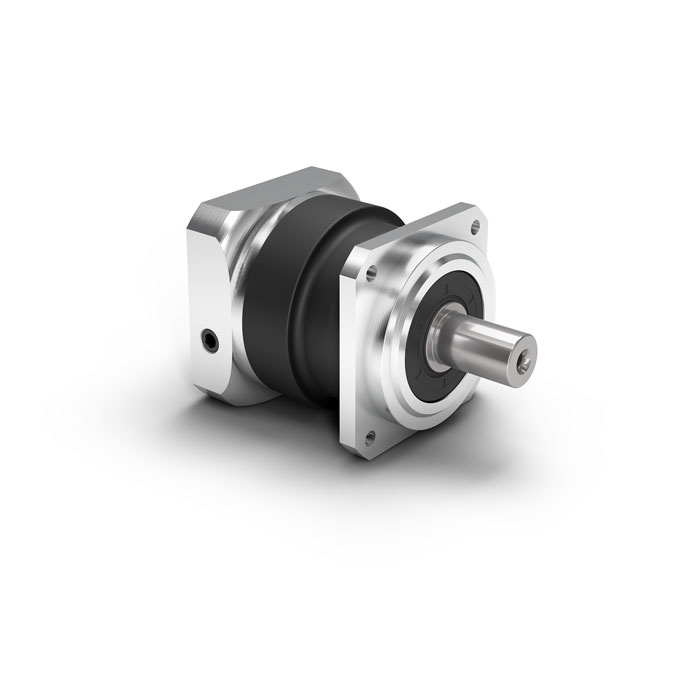

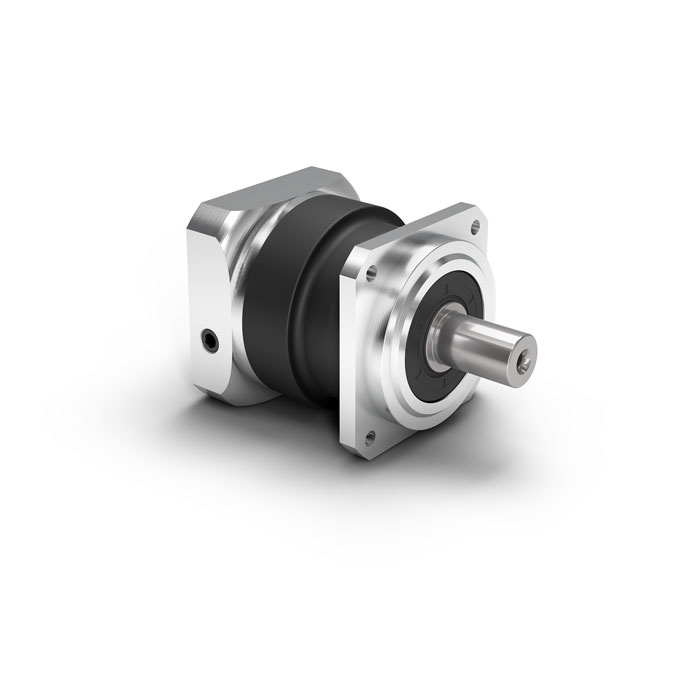

The high-performance precision planetary gearbox with helical teeth for a particularly quiet drive.

Our PSBN is the ideal combination of precision planetary gearbox and efficient bearing technology. It has been developed specifically for delivering the maximum performance at high speeds. Its helical teeth provide homogeneous synchronism and quiet running noise.

PSBN planetary gearbox is a high-performance precision planetary gearbox, equipped with high-precision helical teeth, quiet and noiseless during operation. PSBN is a combination of precision gearbox and high-efficiency bearing. It is designed to achieve excellent performance while ensuring high speed. With the help of high-precision helical teeth, it runs stably and is quieter than ordinary gearboxs.

Product description

The difference between PSBN planetary gearboxes and other models of the NEUGART series is that the new helical teeth of PSBN can achieve optimal uniform synchronous operation. Vibration reduction results in improved workpiece surface quality and printed image quality on the equipment. Thanks to the low friction-loss bearing design and optimized lubrication function at high rotational speeds, the PSBN operates very reliably and generates low heat, even in demanding production cycles. Our self-developed helical teeth can save costs to a certain extent. After using PSBN, there is no need to add additional noise reduction measures to the machine, which increases the value of the entire system.

This PSBN has small return clearance, high precision, and low operating noise. It can be installed at any position. The input flange can be adapted to many types of motors, the rotation direction is the same direction, the output shaft types are diverse, and the service can be customized. Optimized moment of inertia locking system. The helical gear planetary carrier adopts cage structure, low friction deep groove ball bearing. There are four types of structures: PSBN70, PSBN90, PSBN115, and PSBN142 to choose from. The rated torque is 28-470Nm, the radial force is 1000-5800N, the axial force is 1500-9400N, and the return clearance is 1-5arcmin. From this, we can see the PSBN model Suitable for precision workpiece production.

The service life of PSBN gearbox is 20,000 hours, the temperature of the working environment can be as low as -25℃, and the high working temperature can reach 90℃. There are three types of lubrication: standard lubrication, low temperature softening and food grade lubrication. The return clearance can be optimized to be less than 0.01mm, and the torsional stiffness is between 4.1-71Nm, which can be selected. The weight of the gearbox can be selected between 1.4-15.8kg. The radial force of PSBN gearbox can reach 9500N, and the axial force can reach 9600N. 16 speed ratios of the 2-stage planetary carrier can be selected, and the specific gearbox model can be selected according to different application industries. The parameters vary according to different models.

Product advantages

Heat release is still very low at high speed

Inclined gears bring quality improvement

runs very quietly

completely sealed

Can be installed anywhere

Lubricated for life and therefore maintenance-free

Optional

return clearance

Various types of output shafts

Lubricate

Optimized tensioning system

Use

Packaging equipment, pharmaceutical technology and pharmaceutical industry, printing industry

Features

Low noise operation, high precision helical gear, stable operation

| Gearbox characteristics | PSBN070 | PSBN090 | PSBN115 | PSBN142 | P | |

| Reduer | 3, 4, 5, 7, 8, 10 | 1 | ||||

| Reduer | 12,15,16,20,25,35,40,50,70,100 | 2 | ||||

| Service life |

h |

20.000 | ||||

| Service life at T2N×0.88 | h | 30.000 | ||||

| Efficiency at full load | % | 98/96 | ||||

| Min operating temperature/max operating temperature | ℃ | -25/90 | ||||

| Protection class |

IP65 |

|||||

| Standard lubrication | Grease (lifetime lubrication) | |||||

| Food grade lubrication | Grease (lifetime lubrication) | |||||

| Low temperature lubrication | Grease (lifetime lubrication) | |||||

| Installation position | Any | |||||

| Standard backlash | arcmin |

<3-<5 |

||||

| Reduced backlash | arcmin |

<2 |

<1 | <1 | <1 | |

| Torsional stiffness | Nm/arcmin | 4.1-5.7 | 9.3-13.4 | 22.5-35.0 |

57.5-76.0 |

|

| Gearbox weight | kg | 1.4-2.1 | 2.8-3.5 | 5.4-6.9 | 13.4-15.8 | |

| Standard surface | Housing: Steel - heat-treated and post-oxidized(black) | |||||

| Running noise | dB/(A) | 57 | 58 | 63 | 66 | |

| Max bending moment based on the gearbox input flange | Nm | 18 | 18/38 | 38/80 | 80/180 | |

Nominal Output torque

| PSBN070 | PSBN090 | PSBN115 | PSBN142 | I | P |

| 29 | 54 | 135 | 380 | 3 |

1 |

| 39 | 80 | 180 | 470 | 4 | |

| 40 | 80 | 175 | 405 | 5 | |

| 37 | 78 | 175 | 355 | 7 | |

| 39 | 75 | 155 | 350 | 8 | |

| 28 | 59 | 140 | 305 | 10 | |

| 29 | 54 | 135 | 380 | 12 |

2 |

| 29 | 54 | 135 | 380 | 15 | |

| 39 | 80 | 180 | 450 | 16 | |

| 39 | 80 |

180 |

450 | 20 | |

| 40 | 80 | 175 | 405 | 25 | |

| 40 | 80 | 175 | 405 | 35 | |

| 39 | 80 | 180 | 470 | 40 | |

| 40 | 80 | 175 | 405 | 50 | |

| 37 | 78 | 175 | 355 | 70 | |

| 28 | 59 | 140 | 305 | 100 |

Output shaft loads

| PSBN070 | PSBN090 | PSBN115 | PSBN142 | ||

| Radial force for 20000 h | N | 1000 | 1900 | 2300 | 4200-5800 |

| Axial force for 20000 h | N | 1500 | 3000 | 4400 | 9400 |

| Radial force for 30000 h | N | 850 | 1700 | 2000 | 3700-5100 |

| Axial force for 30000 h | N | 1300 | 2500 | 3700 | 7700 |

| Tilting moment for 20000 h | Nm | 68 | 154 | 226 | 565-794 |

| Tilting moment for 30000 h | Nm | 58 | 138 | 197 |

495-697

|

Geometry

| PSBN070 | PSBN090 | PSBN115 | PSBN142 | P | |

| Pitch circle diameter output | 70 | 100 | 130 | 165 | |

| Centering diameter output | 50 | 80 | 110 | 130 | |

| Shaft diameter output | 16 | 22 | 32 |

40 |

|

| Min. total lenght | 116.5 | 140.5 | 182.5 | 247.5 | 1 |

| 145 | 162.5 | 204.5 | 278.5 | 2 | |

| Shaft lenght output | 37 | 48 | 65 | 97 |