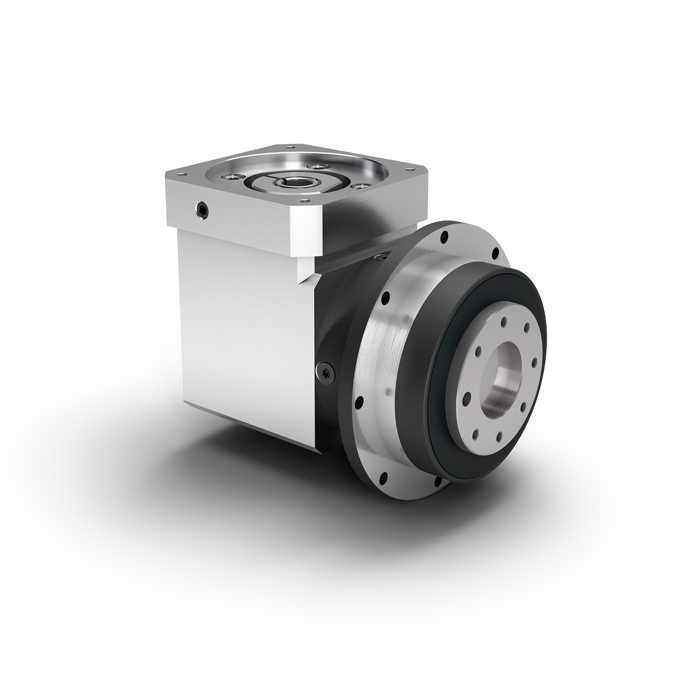

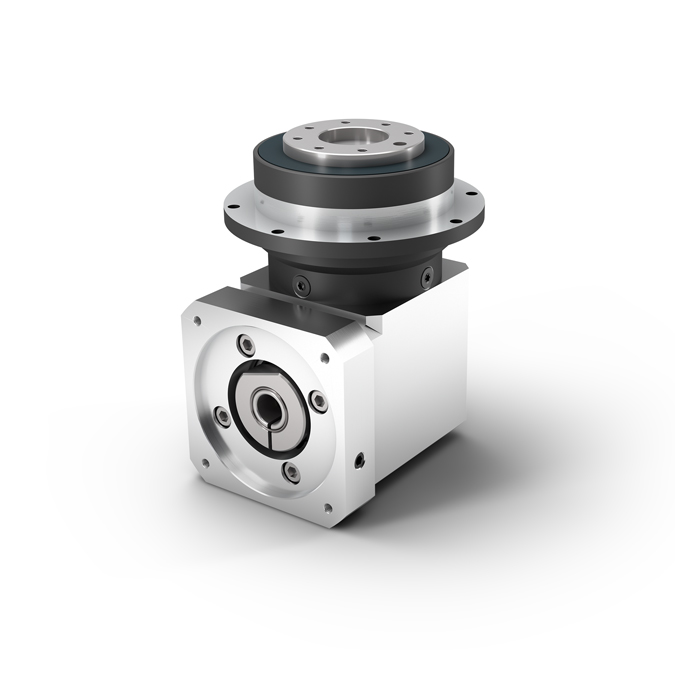

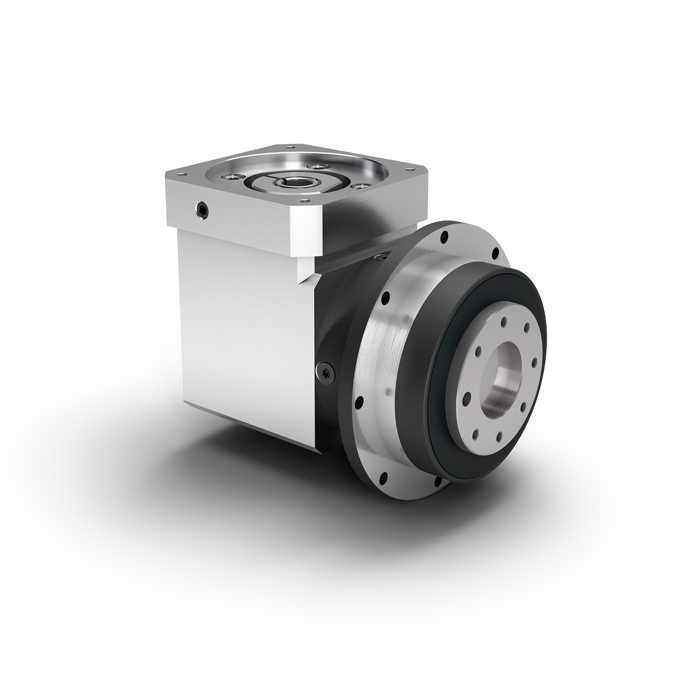

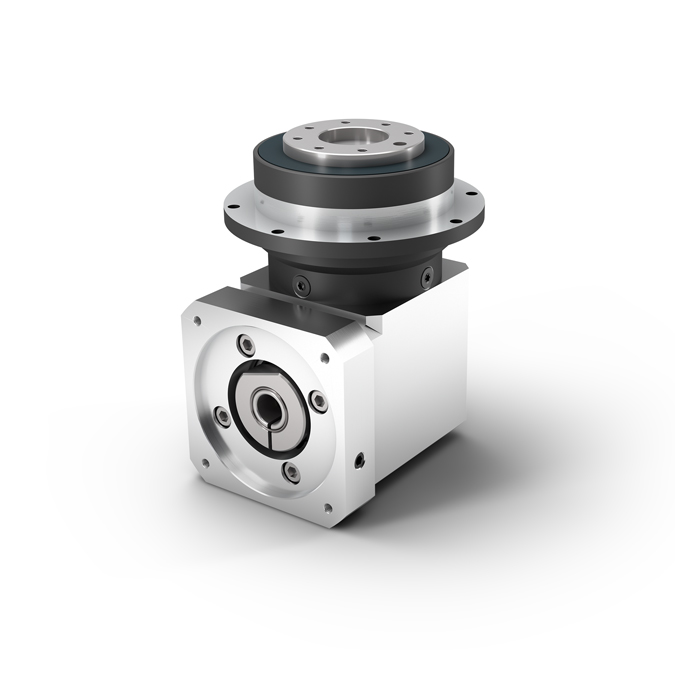

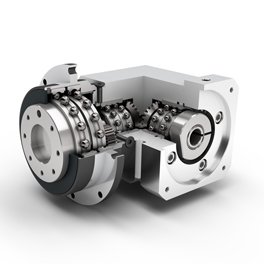

The shortest right angle planetary gearbox with flange output shaft and maximum torsional stiffness.

Thinking around corners even in tight spaces. The WPLFE is our right angle planetary gearbox with compact flange output shaft. You save up to a third of the space and benefit from a torsional stiffness that is five times higher than conventional products. Thanks to its standardized flange interface, it is especially easy to install. The integrated dowel hole provides additional secureness during fitting.

WPLFE planetary reducer is a right-angle planetary reducer of NEUGART series compact flange output shaft, which can save more than one third of the space and has significantly improved torsional rigidity. Thanks to the standardized flange connection, this planetary gearbox is easy to install. Built-in dowel pin holes also provide additional security when securing.

Product description

The standardized flange interface of the WPLFE ensures quick and easy installation of drive components such as belt pulleys, linear elements, turntable feeders, etc. High torsional stiffness for precision drive solutions, due to the larger diameter of the flanged output shaft, the torsional stiffness of the WPLFE is up to five times higher than output shafts with flat keys. From this point of view, the drive scheme of the gearbox can also play an excellent role in cyclic operation and continuous operation. Low installation height saves space. The space required for WPLFE installation is reduced by 30% compared to similar right angle gearboxs.

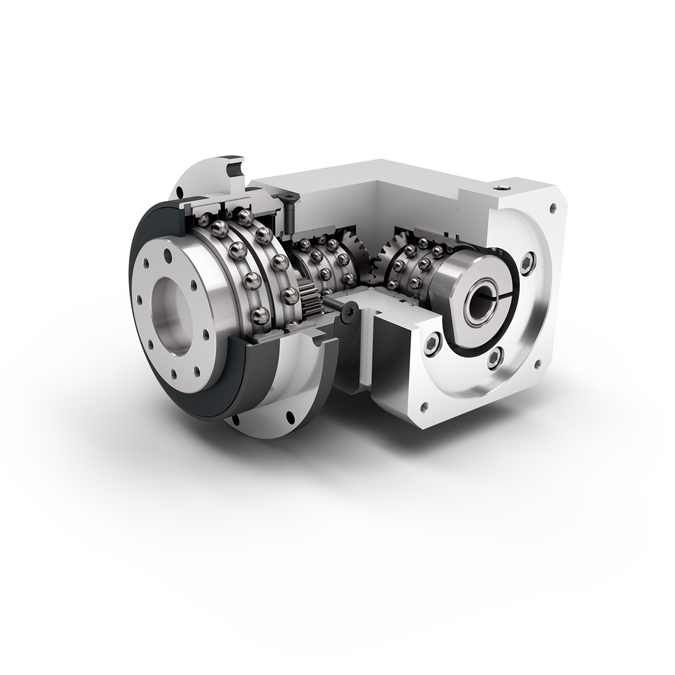

The rated torque of this gearbox is 14-260Nm, the radial force is 550-2400N, the axial force is 1200-3300N, and the return clearance is 11-18arcmin. It adopts round extra large output flange, the flange output shaft adopts ISO 9409 standard, low friction deep groove ball bearing, the working time is 20,000 hours, and the working temperature is between -25-90 ℃. It has three types of food grade, low temperature and standard A lubrication method, the torsional stiffness is 2.9-69Nm, the weight range of the gearbox is 1.8-12.5kg, the radial force can reach 3800N, and the axial force can reach 5200N.

Product advantages

High torsional stiffness for precision drive solutions

Fast and safe installation

Low installation height saves space

High flexibility during installation

Lubricated for life and therefore maintenance-free

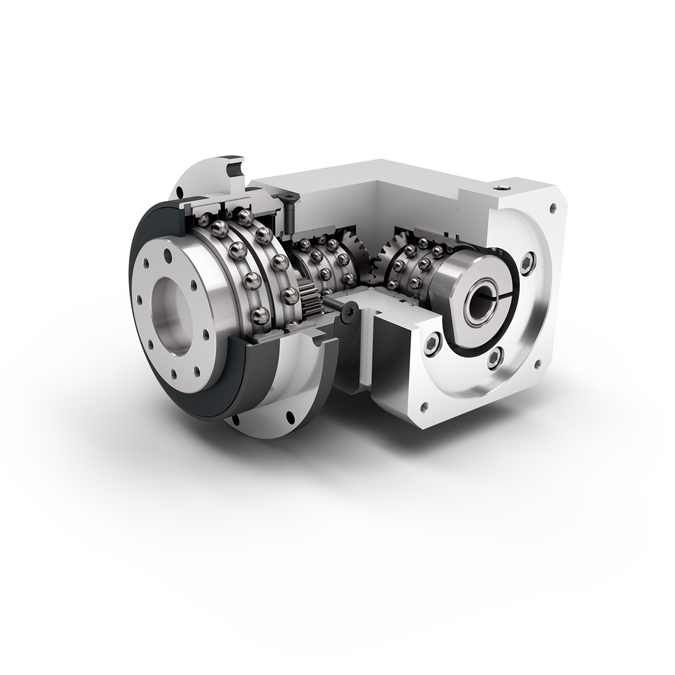

Optimized bearing design for excellent performance

Optional

Lubricate

Various types of drive flanges

Flexible connection of motors

Use

Packaging equipment, machine tools, agricultural products industry

Features

Flange output shaft

save space

Built-in dowel pin hole

Can be installed arbitrarily

Optimized bearing design

| Gearbox characteristics | WPLFE064 | WPLFE90 | WPLFE110 | P | |

| Reduer | 3, 4, 5, 7, 8, 10 | 1 | |||

| Reduer | 9,12,15,16,20,25,32,40,64,100 | 2 | |||

| Service life | h | 20.000 | |||

| Service life at T2N×0.88 | h | 30.000 | |||

| Efficiency at full load | % | 94/93 | |||

| Min operating temperature/max operating temperature | ℃ | -25/90 | |||

| Protection class |

IP54 |

||||

| Standard lubrication | Grease (lifetime lubrication) | ||||

| Food grade lubrication | Grease (lifetime lubrication) | ||||

| Low temperature lubrication | Grease (lifetime lubrication) | ||||

| Installation position | Any | ||||

| Standard backlash | arcmin | <16-<18 | <13-<15 | <11-<13 | |

| Torsional stiffness | Nm/arcmin | 2.9-9.9 | 5.8-29.5 | 15.9-69.0 | |

| Gearbox weight | kg | 1.8-2.1 | 4.5-5.3 | 10.5-12.5 | |

| Standard surface | Housing: Steel - heat-treated and post-oxidized(black) | ||||

| Running noise | dB/(A) | 70 | 73 | 75 | |

| Max bending moment based on the gearbox input flange | Nm | 5 | 10.5 | 26 | |

Nominal Output torque

| WPLFE064 | WPLFE090 | WPLFE110 | I | P |

| 14 | 40 | 80 | 3 |

1 |

| 19 | 53 | 105 | 4 | |

| 24 | 67 | 130 | 5 | |

| 25 | 65 | 135 | 7 | |

| 18 | 50 | 120 | 8 | |

| 15 | 38 | 95 | 10 | |

| 44 | 130 | 210 | 9 |

2 |

| 44 | 120 | 260 | 12 | |

| 44 | 110 | 230 | 15 | |

| 44 | 120 | 260 | 16 | |

| 44 |

120 |

260 | 20 | |

| 40 | 110 | 230 | 25 | |

| 44 | 120 | 260 | 32 | |

| 40 | 110 | 230 | 40 | |

| 18 | 50 | 120 | 64 | |

| 15 | 38 | 95 | 100 |

Output shaft loads

| WPLFE064 | WPLFE090 | WPLFE110 | ||

| Radial force for 20000 h | N | 550 | 1400 | 2400 |

| Axial force for 20000 h | N | 1200 | 3000 | 3300 |

| Radial force for 30000 h | N | 500 | 1200 | 2100 |

| Axial force for 30000 h | N | 1200 | 3000 | 3300 |

| Tilting moment for 20000 h | Nm | 12 | 46 | 109 |

| Tilting moment for 30000 h | Nm | 11 | 40 | 96 |

Geometry

| WPLFE064 | WPLFE090 | WPLFE110 | P | ||

| Pitch circle diameter output shaft | mm | 31.5 | 50 | 63 | |

| Centering diameter output flange | mm | 64 | 90 | 110 | |

| Flange diameter output | mm | 86 | 118 | 145 | |

| Min. total lenght | mm | 110 | 149 | 198.5 | 1 |

| mm | 122.5 | 165.5 | 225.5 | 2 | |

| Output flange length | mm | 19.5 | 30 | 29 |