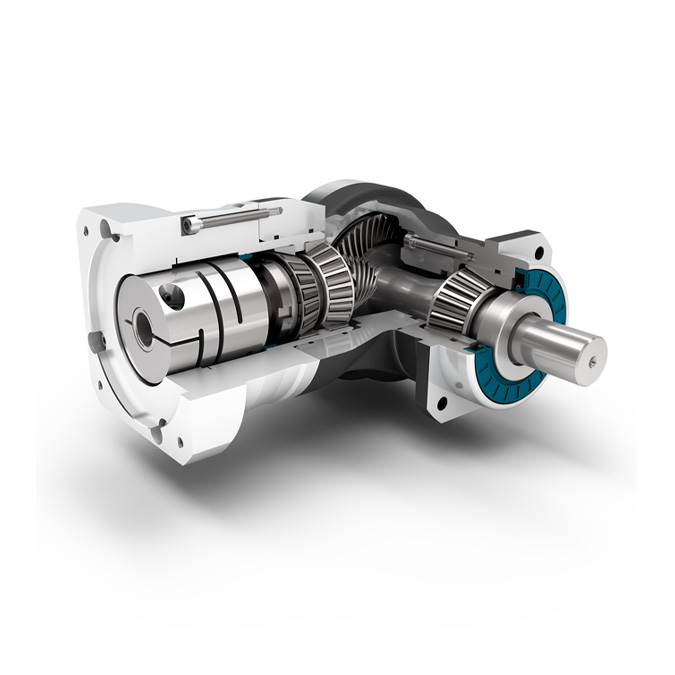

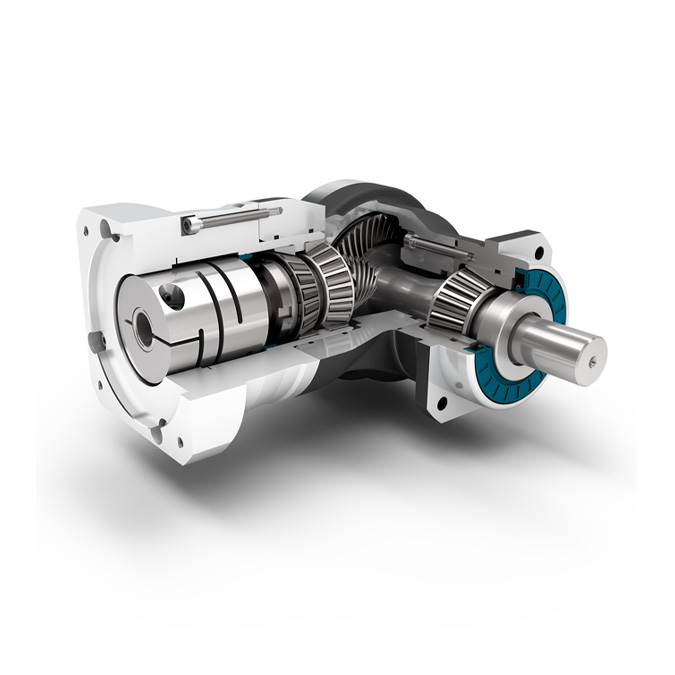

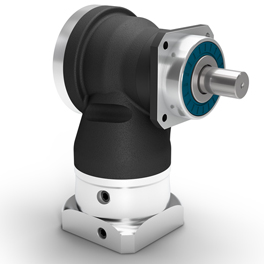

The versatile right angle gearbox with spiral teeth for a quiet drive.

Thanks to its spiral teeth, our WPLN achieves the optimal synchronism for the best surface qualities. By minimizing vibrations, it runs uniformly and quietly. The precision right angle planetary gearbox features lifetime lubrication and can be mounted virtually anywhere.

WPLN right-angle gearboxes are equipped with hypoid, so they operate very quietly. Thanks to its hypoid gears, the synchronous running performance of the WPLN is optimized and the surface quality of the workpiece workpieces applied can reach a high level. With minimal vibration, the WPLN operates stably and quietly. This high-precision right-angle gearbox is lubricated for life and maintenance-free, and can be installed in any position.

Product description

The WPLN right angle gearbox is highly flexible when installed. This hypoid gear planetary gearbox, which has been lubricated for life, can play a good role in the case of a small operating space. The WPLN can be installed in any position, thus creating a more more free space. Very quiet operation, high-quality hypoid gears make the WPLN operate with low noise and no additional noise reduction measures are required on the machine, thereby increasing the overall value of the system. Excellent manufacturing results, because equipped with hypoid gears, the WPLN operates very stably and with low vibration amplitude, so that the workpiece processing of the application equipment can achieve excellent surface and printing quality. The input flange of this gearbox can be adapted to a special motor, the direction of rotation is reversed, the output shaft can be selected in a variety of ways, and the optimized moment of inertia locking system. The square output flange is adopted, the radial shaft seal, the return clearance can be selected, the rated torque is 22-800Nm, the radial force is 3200-12500N, the axial force is 4300-15000N, the return clearance is 3-5 arc minutes, and the service life is 20000h. The working temperature is -25-90℃. The specific model parameters are mainly based on the selection situation.

Product advantages

High flexibility during installation

runs very quietly

Excellent processing quality

High rigidity under high loads

completely sealed

Individually adjustable drive flange on the motor

Optional

Various types of output shafts

return clearance

Lubricate

Optimized tensioning system

Various types of drive flanges

installed pinion

Use

Packaging equipment, machine tool equipment, printing equipment, lithium battery industry

Features

Low noise, high precision, small size

| Gearbox characteristics | WPLN070 | WPLN090 | WPLN115 | WPLN142 | P | |

| Reduer | 4, 5, 7, 8, 10 | 1 | ||||

| Reduer | 16,20,25,28,32,35,40,50,64,100 | 2 | ||||

| Service life |

h |

20.000 | ||||

| Service life at T2N×0.88 | h | 30.000 | ||||

| Efficiency at full load | % | 95/94 | ||||

| Min operating temperature/max operating temperature | ℃ | -25/90 | ||||

| Protection class |

IP65 |

|||||

| Standard lubrication | Grease (lifetime lubrication) | |||||

| Food grade lubrication | Grease (lifetime lubrication) | |||||

| Installation position | Any | |||||

| Standard backlash | arcmin | <5 | ||||

| Reduced backlash | arcmin | <3 | ||||

| Torsional stiffness | Nm/arcmin | 1.8-3.6 | 4.6-8.6 | 8.6-16.9 | 24.5-34.0 | |

| Gearbox weight | kg | 3.4-4.5 | 5.4-5.9 | 10.4-11.3 | 24.626.5 | |

| Standard surface | Housing: Steel - heat-treated and post-oxidized(black) | |||||

| Running noise | dB/(A) | 66 | 67 | 68 | 70 | |

| Max bending moment based on the gearbox input flange | Nm | 12 | 12/25.5 | 25.5/53 | 53/120 | |

Nominal Output torque

| WPLN070 | WPLN090 | WPLN115 | WPLN142 | I | P |

|

45 |

90 | 160 | 320 | 4 |

1 |

| 42 | 75 | 140 | 280 | 5 | |

| 28 | 51 | 91 | 189 | 7 | |

| 27 | 50 | 90 | 180 | 8 | |

| 22 | 40 | 75 | 160 | 10 | |

| 77 | 150 | 300 | 640 | 16 | 2 |

| 77 | 150 | 300 | 800 | 20 | |

| 65 | 140 | 260 | 700 | 25 | |

| 60 | 112 | 204 | 364 | 28 | |

| 77 | 108 | 200 | 360 | 32 | |

| 65 | 140 | 255 | 455 | 35 | |

| 65 | 135 | 250 | 450 | 40 | |

| 65 | 110 | 200 | 375 | 50 | |

| 40 | 80 | 150 | 450 | 64 | |

| 27 | 60 | 125 | 305 | 100 |

Output shaft loads

| WPLN070 | WPLN090 | WPLN115 | WPLN142 | |

| Radial force for 20000 h | 3200 | 5200 | 6000 | 12500 |

| 3200 | 5500 | 6000 | 12500 | |

| Axial force for 20000 h |

4300 |

5900 | 7000 | 14500 |

| 4400 | 6400 | 8000 | 15000 | |

| Radial force for 30000 h | 3200 | 5200 | 6000 | 10900 |

| 3200 | 4800 | 5400 | 11400 | |

| Axial force for 30000 h | 3700 | 5200 | 6100 | 12000 |

| 3900 | 5700 | 7000 | 13200 | |

| Tilting moment for 20000 h | 322 | 624 | 1010 | 2225 |

| 322 | 660 | 1010 | 2225 | |

| Tilting moment for 30000 h | 322 | 624 | 1010 | 1940 |

| 322 | 576 | 909 | 2029 |

Geometry

| WPLN070 | WPLN090 | WPLN115 | WPLN142 | P | |

| Shaft diameter output |

16 |

22 | 32 | 40 | |

| Centering diameter output | 60 | 70 | 90 | 130 | |

|

Flange cross section output |

70 |

80 | 110 | 142 | |

|

Min. total lenght |

137.5 | 165 | 218 | 273 | 1 |

| 185 | 207 | 248.5 | 342.5 | 2 | |

| Shaft lenght output | 48 | 56 | 88 | 110 |