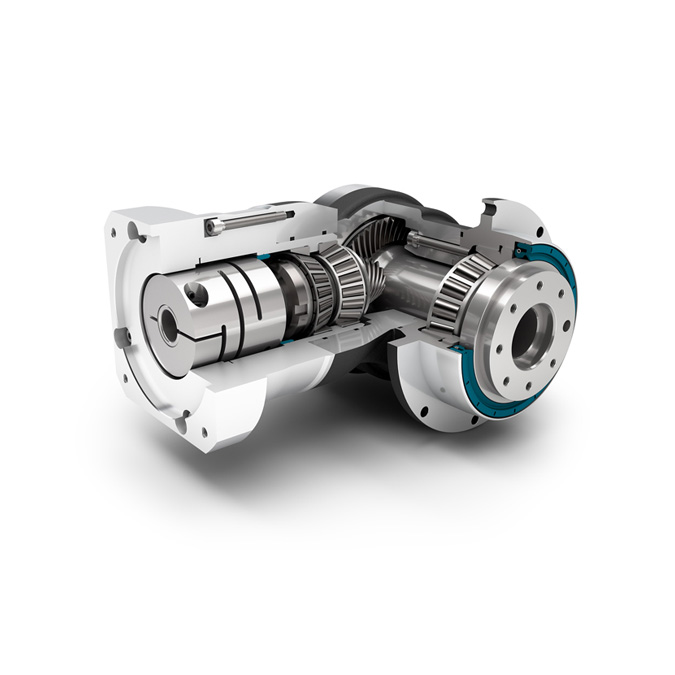

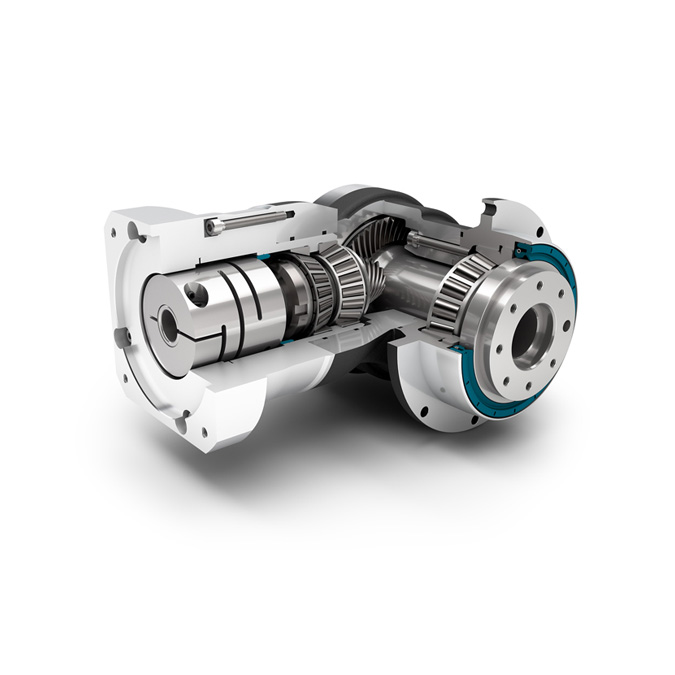

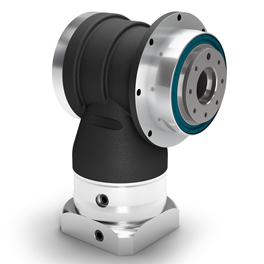

The shortest spiral-toothed right angle gearbox with flange output shaft and hollow shaft.

Our WPSFN is extremely light and easy to integrate thanks to its standardized flange interface. It achieves optimized synchronization with the spiral gearing and the helical-toothed planetary stage for the best surface qualities. The shortest right angle precision gearbox with integrated hollow shaft provides you with new structural solutions.

WPSFN hollow shaft planetary gearbox. The shortest hypoid right-angle gear units with flanged output shaft and hollow shaft Our WPSFN series can be integrated into systems extremely easily and quickly thanks to their standardized flange interface. Synchronized running performance is greatly optimized to achieve excellent surface quality by means of hypoid gears and helical planetary systems. The shortest right-angle precision gearbox, with integrated hollow shaft output, brings you a new output connection solution.

Product description

The hollow shaft gearbox of WPSFN flange output is a right-angle gearbox, which can play the best effect in a limited space; the use of hypoid gears further improves the processing quality of the gearbox; it is equipped with preloaded angular contact Roller bearing, round extra large output flange, can choose to reduce the return clearance, rated torque 22-625Nm, radial force 2150-12000N, axial force 4200-9500N, return clearance 3-5 arc minutes. The service life of this gearbox is 20000h, the working temperature range is -25-90℃, there are three lubrication methods of standard, low temperature and food grade, and the torsional stiffness range is 1.9-111Nm. Different specifications and models have different selection parameters. type parameter. Our angular planetary gear units with output flange stand out for their compact flange connection. The right-angle construction facilitates space-saving positioning of the drive system, giving you maximum design freedom.

The geometry of the output side of the planetary gearbox is oriented towards the most common industrial robots. The advantage of dimensioning according to EN ISO 9409-1 is the quick and easy connection of other drive components such as turntables, linear units or couplings that comply with the standard. This makes it easy and quick to establish the mechanical connection of the planetary gearbox with output flange to your machine. In addition, the connection between the planetary gear unit and the machine tool is secured by locating pin holes built into the output flange. Due to the compact design, the flanged output shaft is not only very space-saving, but also has a high torsional strength. This advantageous characteristic of the gear unit is confirmed when driving turntables or other components: high precision and fast cycling, even when the direction of movement is alternated. The drive flange of the angular planetary gearbox can be individually adapted to the motor. The compact unit of angle gearbox and servo motor increases flexibility.

For added structural flexibility, the angular planetary gearbox with output flange is lubricated for life and can be installed and used in all spatial positions due to its design. Therefore, you can flexibly design the construction space regardless of the positioning of the drive unit.

Product advantages

Low installation height saves space

Improve quality with high-grade gear teeth

Standardized flange connection with hollow shaft

completely sealed

runs very quietly

Can be installed anywhere

Optional

Various types of output shafts

return clearance

Lubricate

Optimized tensioning system

Various types of drive flanges

installed pinion

Use

Packaging equipment, machine tools, food industry

Features

Quiet operation, precision type, flange interface

| Gearbox characteristics | WPSFN064 | WPSFN090 | WPSFN110 | WPSFN140 | P | |

| Reduer | 4, 5, 7, 8, 10 | 1 | ||||

| Reduer | 16, 20, 25, 28, 32, 35, 40, 50, 70,100 | 2 | ||||

| Service life |

h |

20.000 | ||||

| Service life atT2N×0.88 | h | 30.000 | ||||

| Efficiency at full load | % | 94/93 | ||||

| Min operating temperature/max operating temperature | ℃ | -25/90 | ||||

| Protection class |

IP65 |

|||||

| Standard lubrication | Grease (lifetime lubrication) | |||||

| Food grade lubrication | Grease (lifetime lubrication) | |||||

| Installation position | Any | |||||

| Standard backlash | arcmin | <5 | ||||

| Reduced backlash | arcmin | <3 | ||||

| Torsional stiffness | Nm/arcmin | 1.9-6.9 | 4.0-20.0 | 10.1-44.0 | 26.0-111.0 | |

| Gearbox weight | kg | 3.5-4.0 | 5.6-7.0 | 9.0-11.7 | 19.2-26.0 | |

| Standard surface | Housing: Steel - heat-treated and post-oxidized(black) | |||||

| Running noise | dB/(A) | 66 | 67 | 68 | 70 | |

| Max bending moment based on the gearbox input flange | Nm | 12 | 12/25.5 | 25.5/53 | 53/120 | |

Nominal Output torque

| WPSFN064 | WPSFN090 | WPSFN110 | WPSFN140 | I | P |

| 45 | 90 | 160 | 320 | 4 |

1 |

| 42 | 75 | 140 | 280 | 5 | |

| 28 | 51 | 91 | 189 | 7 | |

| 27 | 50 | 90 | 180 | 8 | |

| 22 | 40 | 75 | 160 | 10 | |

| 62 | 130 | 310 | 625 | 16 |

2 |

| 62 | 130 | 300 | 560 | 20 | |

| 60 | 120 | 255 | 540 | 25 | |

| 62 | 112 | 204 | 364 | 28 | |

| 62 | 108 | 200 | 360 | 32 | |

| 60 | 123 | 255 | 455 | 35 | |

| 60 | 123 | 250 | 450 | 40 | |

| 60 | 110 | 200 | 375 | 50 | |

| 37 | 78 | 175 | 355 | 70 | |

|

28 |

59 | 140 | 305 | 100 |

Output shaft loads

| WPSFN064 | WPSFN090 | WPSFN110 | WPSFN140 | |

| Radial force for 20000 h | 2400 | 4400 | 5500 | 12000 |

| 2150 | 3950 | 4900 | 12000 | |

| Axial force for 20000 h | 4200 | 7200 | 9500 | 8500 |

| 4300 | 8200 | 9500 | 8500 | |

| Radial force for 30000 h | 2100 | 3900 | 4800 | 11000 |

| 1900 | 3500 | 4350 | 11000 | |

| Axial force for 30000 h | 3700 | 6300 | 8400 | 7500 |

| 3800 | 7200 | 8400 | 7500 | |

| Tilting moment for 20000 h | 200 | 484 | 689 | 1989 |

| 132 | 326 | 475 | 1030 | |

| Tilting moment for 30000 h | 175 | 429 |

601 |

1823 |

| 117 | 289 | 422 | 944 |

Geometry

| WPSFN064 | WPSFN090 | WPSFN110 | WPSFN140 | P | |

| Pitch circle diameter output shaft |

31.5 |

50 | 63 | 80 | |

| Centering diameter output flange | 64 | 90 | 110 | 140 | |

| Flange diameter output | 86 | 118 | 145 | 179 | |

| Hollow shaft diameter | 17 | 25 | 35 | 50 | 1 |

| Min. total lenght | 104.5 | 132 | 153.5 | 201.5 | 1 |

| 122.5 | 139.5 | 154 | 224 | 2 | |

| Output flange length | 19.5 | 30 | 29 | 38 |